Self-Supporting Angular Telecom Towers

September 27, 2025

Unpacking the Differences Between Self-Support Tower and Guyed Towers

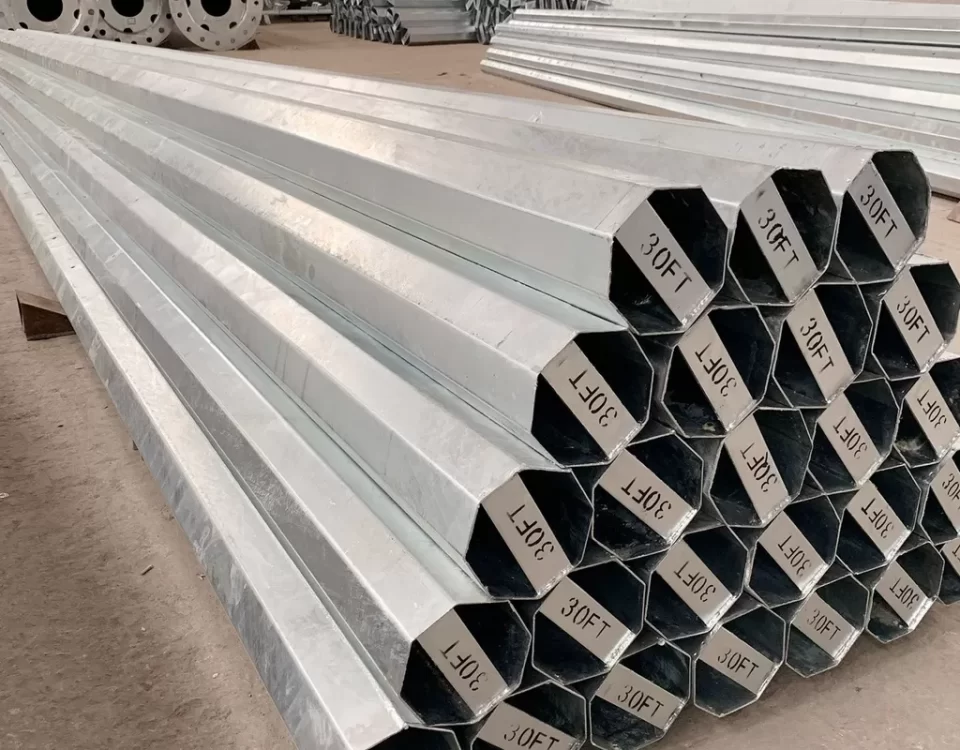

October 11, 2025Polygonal Steel Distribution Poles for power transmission

Engineering Reliability: The Definitive Guide to High-Performance Polygonal Steel Distribution Poles

Introduction: The Backbone of Modern Power Infrastructure

The uninterrupted delivery of electrical power is the foundation of economic stability and societal function. As infrastructure ages and demands for smart grid integration, increased resilience, and aesthetic harmonization grow, the role of the humble utility pole has evolved into a highly engineered structural component.

Our company stands at the forefront of this evolution, specializing in the design and manufacture of Polygonal Steel Distribution Poles for power transmission. These poles are not merely supports; they are meticulously engineered, high-performance assets designed to endure extreme environmental loads and safely manage electrical power across an extensive voltage spectrum, ranging from low-tension 220V circuits to crucial 69kV sub-transmission lines.

Our commitment to unparalleled quality is evidenced by our rigid adherence to global manufacturing standards—including AWS D1.1, CSA W47.1, and comprehensive corrosion protection standards such as ASTM A123, ISO 1461, and AS/NZS 4680. Coupled with the utilization of high-yield materials like Q355 and ASTM A572 Grade 65—with manufacturing capabilities extending up to 35mm and 24mm wall thicknesses, respectively—our poles are engineered for guaranteed performance, longevity, and structural superiority under the strict oversight of our ISO 9001:2015 Quality Management System.

This document provides a comprehensive analysis of the engineering principles, material science, fabrication methodologies, and quality assurances that define the market-leading superiority of our polygonal steel distribution poles.

I. Structural Design Philosophy: The Polygonal Pole Advantage

The selection of the pole profile is the critical starting point in structural design. The Polygonal Pole—typically featuring 8, 12, or 16 sides—is the definitive choice for modern power delivery, offering decisive engineering benefits over traditional wood, concrete, or even lattice structures.

1.1 Optimizing Load Management and Structural Efficiency

The primary structural requirement for a power pole is its ability to resist massive bending moments generated by external forces, including maximum wind speed, ice loading, conductor tension, and seismic activity. The polygonal cross-section excels in this regard:

- Strength-to-Weight Ratio: The faceted geometry maximizes the moment of inertia for a given cross-sectional area compared to a uniform circular section that requires thicker walls to achieve similar bending resistance. This optimization leads to a significantly lighter pole structure, which drastically reduces material costs, transportation logistics, and the size requirements for foundations—a major cost factor in utility projects.

- Taper and Flexibility: Our poles are continuously tapered, meaning the diameter decreases from the base to the top. This continuous geometric adjustment ensures that material thickness and diameter are proportional to the calculated internal stresses at every point along the pole’s height. This meticulous design prevents material waste while guaranteeing that the structure remains within safe limits.

- Reduced Drag Coefficient: The smooth, tapered polygonal surface presents a lower effective surface area to the wind compared to the open framework of a lattice tower. This reduction in the wind drag coefficient translates directly into lower lateral loading, allowing the use of lighter sections for a given wind speed and resulting in a more resilient structure during extreme weather events.

1.2 Aesthetic and Logistical Benefits

Beyond pure mechanics, the polygonal design offers essential practical advantages:

- Visual Integration: The clean, slender profile is aesthetically superior to bulky concrete or visually busy lattice towers. This makes polygonal poles the preferred solution for installations in urban, suburban, and scenic corridors where visual impact is a high-stakes consideration.

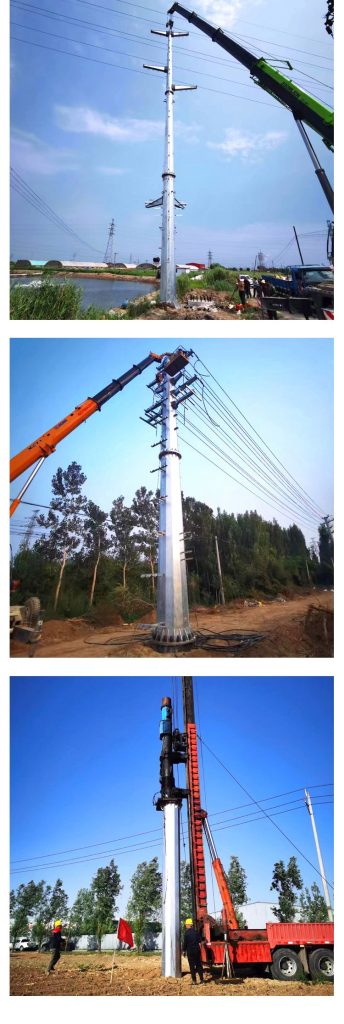

- Ease of Erection: Single-shaft steel poles are significantly faster to erect than sectional lattice towers. Furthermore, the smooth surface simplifies climbing, maintenance, and the mounting of specialized electrical equipment, leading to reduced maintenance costs and faster commissioning times.

II. Material Science and Structural Integrity

The mechanical properties of the steel define the ultimate load-bearing capacity and resilience of the pole. We offer an extensive portfolio of high-yield structural steels, enabling us to match the material choice precisely to the design load and regional specification requirements.

2.1 The High-Yield Material Portfolio

We predominantly use high-yield steel grades, defined by their minimum specified Yield Strength (fy)—the stress level at which the material begins to permanently deform.

| Material Grade | Specification Basis | Minimum Yield Strength (fy) (MPa) | Minimum Tensile Strength (fu) (MPa) | Typical Pole Application |

| Q235 | Chinese National Standard | 235 | 370−500 | Light-duty, low-voltage distribution lines. |

| Q355 | Chinese National Standard | 355 | 470−630 | Standard utility pole; primary choice for medium to high loads. |

| Q420 | Chinese National Standard | 420 | 520−680 | High-strength feeder lines; maximizing height-to-weight ratio. |

| Q460 | Chinese National Standard | 460 | 550−720 | Critical poles requiring maximum strength; equivalent to some API grades. |

| ASTM A572 Gr65 | US Standard (ASTM) | 450 (approx. 65ksi) | 620 (approx. 90ksi) | Standard choice for North American, Australian, and international projects requiring US specification. |

2.2 Fabrication Capacity and Wall Thickness

Our manufacturing capability is a direct function of the high-grade materials we process. The thickness of the steel plate is critical for pole stiffness and ultimate load capacity, especially near the base where bending moments are highest.

We possess the specialized press braking equipment and welding technology to handle:

- Up to 35mm thickness for Q355: This maximum thickness capability is crucial for extremely heavy-duty poles, such as those used in corner locations, high-tension dead-end poles, or structures supporting heavy distribution substation feeders. Utilizing 35mm Q355 steel provides enormous structural capacity, enabling us to design and manufacture poles exceeding 50m in height under heavy loading conditions.

- Up to 24mm thickness for ASTM A572 Gr65: This limit demonstrates our capacity to handle the specific mechanical properties of high-yield steel used in international projects, ensuring that the forming and welding processes maintain the integrity of the Gr65 material without compromising its 450 MPa yield strength.

This capability is essential for competitive advantage, as many manufacturers are limited to 15mm or 20mm plate thickness, restricting them from participating in high-load 69kV and 115kV structures.

III. Precision Fabrication: The Welding and Quality Assurance Guarantee

The strength of a polygonal pole originates from its single, continuous longitudinal seam weld. The quality of this weld is non-negotiable and is guaranteed by our strict adherence to the world’s most recognized welding standards.

3.1 Certified Welding Excellence

Our welding procedures and personnel are certified to meet or exceed:

- AWS D1.1 (American Welding Society): This is the definitive code for structural welding in the United States. Compliance ensures that our welding electrodes, procedures (WPS), pre-heat/post-weld heat treatment requirements, and welder qualifications meet the highest standard for critical, high-stress structures. This standard is widely accepted globally as a benchmark for quality.

- CSA W47.1 (Canadian Welding Bureau – CWB): This certification demonstrates our expertise in meeting the specific structural welding standards required for Canadian infrastructure projects. Compliance involves rigorous third-party auditing of our welding procedures, equipment, and personnel qualifications, showcasing our adaptability to stringent international codes.

The application of submerged arc welding (SAW) for the long, single longitudinal seam ensures deep penetration, minimal porosity, and a smooth, consistent weld bead that resists fatigue cracking over the pole’s lifetime.

3.2 ISO 9001:2015 Quality Management

Quality assurance is not a final check but an integrated process governed by our ISO 9001:2015 certification. This QMS covers every step, ensuring:

- Material Traceability: Every steel plate section is tracked from mill receipt through cutting, forming, welding, and galvanizing. This allows us to link the final pole to the original material test certificates (MTCs), ensuring the Gr65 or Q355 specified was actually used.

- Dimensional Control: The precision of the taper, the overall length, and especially the diameter and polygonal shape are crucial for structural integrity and connection fit-up (slip joints). Continuous monitoring ensures all dimensions adhere to the design tolerance.

- Non-Destructive Examination (NDE): Weld quality is verified through NDE techniques, including Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT) on critical weld areas to detect any subsurface discontinuities before galvanizing.

IV. Assembly Efficiency: Slip Joints vs. Flange Joints

Modern steel poles, especially those exceeding 30m in height, are typically manufactured in two or more sections for logistical reasons (transportation and handling). Our dual-connection strategy maximizes efficiency and structural rigidity.

4.1 Slip Joint Technology: The Friction Fit

The Slip Joint is the standard and most efficient connection method for multi-section poles:

- Mechanism: The joint relies on a precise interference fit created by the continuous taper of the pole. The top section is forced down onto the bottom section, creating immense frictional resistance and a highly rigid connection.

- Field Benefits: Eliminates the need for tedious field welding or bolting. Erection is simplified and accelerated; once the top section is slipped into place using the weight of the rigging, the connection is complete and structurally sound.

- Structural Performance: When properly engaged, the slip joint performs structurally as a continuous, unsegmented piece of steel, ensuring the moment transfer capacity is maintained across the entire structure.

4.2 Flange Joint Technology: Absolute Rigidity

Flange Joints are primarily used for connecting the base of the pole to the concrete foundation and, occasionally, in special intermediate connections:

- Rigidity: Flange joints provide a fixed, absolute connection using high-strength bolts (typically ASTM A325 or equivalent). This is essential at the base, where the connection must transfer the entire overturning moment and shear force into the anchor bolts and foundation.

- Controlled Alignment: Flange joints, especially at the base, allow for precise final plumbing (vertical alignment) of the pole during erection by adjusting the leveling nuts.

V. Electrical Versatility: Designing for the Voltage Spectrum

The mechanical structure must be seamlessly integrated with electrical safety requirements. Our poles are custom-designed to accommodate the specific clearances, insulator types, and conductor configurations necessary for a broad range of operational voltages.

| Voltage Classification | Range (V/kV) | Primary Electrical Design Constraint | Typical Mechanical Configuration |

| Low Voltage | 220V,1kV | Insulation integrity and conductor spacing. | Single or double tangent structures; simple horizontal cross-arms. |

| Medium Voltage | 3kV to 33kV | Flashover distance and NESC/IEC minimum clearances. | Vertical arrays (delta configuration), distribution platforms, longer horizontal arms. |

| Sub-Transmission | 69kV | Air gap, radio interference limits (RIV), and insulator string length. | Requires taller poles, significant separation between phases, and dedicated conductor termination structures. |

The steel’s high conductivity requires careful attention to grounding design. The pole is inherently a grounded structure, and our design ensures that all attachments (cross-arms, platforms) maintain the requisite insulation standoff distance to prevent flashover, even in contaminated or wet environments.

VI. Longevity and Environmental Resilience: Multi-Standard Hot Dip Galvanizing

The service life of a steel pole—often expected to exceed 50 years—is entirely reliant on its corrosion protection. We achieve this longevity through an uncompromising Hot Dip Galvanizing (HDG) process certified to multiple international standards.

6.1 The HDG Process and Sacrificial Protection

HDG involves submerging the fully fabricated pole section into a bath of molten zinc (approx. 450∘C). This forms a metallurgical bond, creating a series of iron-zinc alloy layers that are far harder and more durable than the base steel. This coating provides:

- Barrier Protection: A physical shield against the atmosphere.

- Sacrificial (Cathodic) Protection: If the coating is scratched, the zinc surrounding the damaged area corrodes preferentially to the underlying steel, preventing rust migration and guaranteeing integrity.

6.2 Global Compliance with Triple Certification

Our ability to certify the coating to three primary standards demonstrates global quality assurance and flexibility for international projects:

| Standard | Geographic Focus | Key Requirement Focus | Primary Benefit |

| ASTM A123 | North America | Minimum coating weight (oz/ft2) based on the structural thickness. | US and Canadian market compliance; defined coating durability. |

| ISO 1461 | International | Minimum coating thickness (μm) based on the steel thickness. | Universally accepted benchmark for HDG quality and thickness. |

| AS/NZS 4680 | Australia/New Zealand | Highly rigorous standards for thickness and surface finish, crucial for harsh coastal and industrial environments. | Proves resilience in extreme corrosive environments. |

This multi-standard certification means that regardless of the site environment—from arid inland regions to humid, highly corrosive coastal zones—our pole coatings are verified to provide the necessary level of long-term protection. We ensure a typical 100μm (micron) minimum thickness is achieved, guaranteeing the pole will remain structurally sound for decades with minimal maintenance.

VII. Consolidated Technical Parameters and Manufacturing Capabilities

The following tables summarize the critical engineering specifications and capabilities that define our Steel Distribution Pole products.

7.1 Material Mechanical Properties and Thickness Capacity

| Material Grade | Specification | Minimum Yield Strength (fy) | Maximum Plate Thickness Capacity | Key Use |

| Q235 | GB/T 700 | 235 MPa | Custom | Low-load/Secondary structures. |

| Q355 | GB/T 1591 | 355 MPa | 35mm | Heavy-duty, standard utility poles. |

| Q420 | GB/T 1591 | 420 MPa | Custom | High stress/Height-to-weight optimization. |

| Q460 | GB/T 1591 | 460 MPa | Custom | Extreme load conditions. |

| ASTM A572 Gr65 | ASTM A572 | 450 MPa (approx) | 24mm | International project specification. |

7.2 Manufacturing and Compliance Summary

| Parameter | Specification | Standard/Certification | Compliance Requirement |

| Pole Type | Polygonal Steel Pole (8/12/16 Sided) | Custom Engineering | Optimized for bending moment and wind load. |

| Welding | Longitudinal Seam (SAW) | AWS D1.1, CSA W47.1 (CWB) | Guarantees structural integrity and weld quality. |

| Corrosion Protection | Hot Dip Galvanizing (HDG) | ASTM A123, ISO 1461, AS/NZS 4680 | Multi-standard compliance for 50+ year service life. |

| Quality System | Process Control & Traceability | ISO 9001:2015 | Ensures material integrity, dimensional accuracy, and documentation. |

| Connection Types | Slip Joints, Flange Joints | Proprietary Taper/Design | High-speed assembly and superior structural rigidity. |

7.3 Voltage Accommodation and Application

| Voltage Range | Typical Application | Insulation/Clearance Requirement | Associated Design Challenge |

| 220V to 10kV | Local distribution, service drops, municipal. | Low-to-Medium Voltage insulation (e.g., ceramic or polymer line posts). | Managing conductor sag and weight for closely spaced lines. |

| 33kV | Feeder/Main Distribution Lines. | Medium Voltage insulation strings/standoffs. | Designing for increased pole height and heavier equipment loads (transformers/switches). |

| 69kV | Sub-Transmission Lines. | High Voltage polymer/glass suspension insulators. | Meeting minimum air gap clearances and handling extreme conductor tension forces. |

Conclusion: Delivering Sustainable Power Reliability

Our Polygonal Steel Distribution Poles represent the ideal synergy of advanced engineering, high-yield material science, and uncompromising quality control. By leveraging the structural efficiency of the polygonal profile and utilizing high-capacity materials like Q355 up to 35mm thickness, we provide poles that are structurally superior and more resilient than conventional alternatives.

From our globally certified welding procedures (AWS D1.1, CSA W47.1) to our triple-standard corrosion protection (ASTM A123, ISO 1461, AS/NZS 4680), every stage of our manufacturing process is meticulously managed under ISO 9001:2015. This dedication ensures that whether the pole is supporting a simple 220V service or a crucial 69kV feeder line, it delivers a lifetime of safe, reliable, and aesthetically sound power transmission performance. We are committed to powering the future with infrastructure built to last.

Related posts

In low-voltage transmission networks, which typically operate below 1,000 volts, galvanized steel poles provide a durable and environmentally friendly solution. This article explores the features, benefits, applications, and technical specifications of low voltage galvanized steel utility poles in transmission line projects.

Hot Dip Galvanized Electrical Metal Utility Steel Pole for Railway in Shape Octagonal widely used in electrical power transmission railway station industry. In order to meet the increasingly higher demand for steel poles, our company design and produce many kinds of steel poles for the power transmission and distribution system. Besides, our electrical steel poles have been tested and approved by the Transmission Pole Tower Testing Station.