Steel Tower Maintenance, Operations Support and Communication Network Optimization

November 15, 2025

communications tower – Quality Control and Non-Destructive Testing (NDT)

November 25, 2025

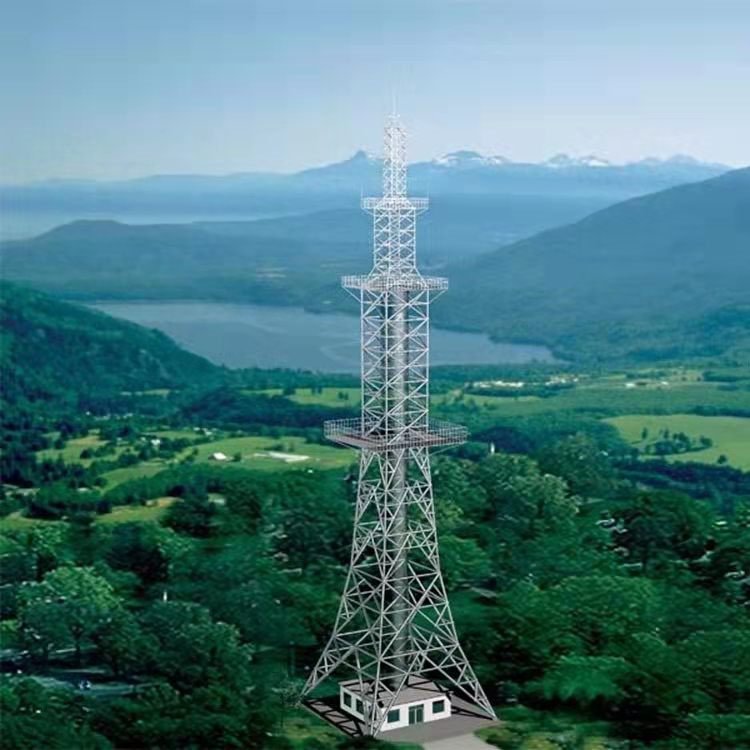

The engineering challenge posed by the design and maintenance of Seismic-Resistant Communication Towers elevates the task from standard structural engineering to a critical discipline of national resilience and infrastructure continuity, recognizing that in the immediate aftermath of a major seismic event, the ability of communication networks to remain operational is not merely a convenience but a matter of public safety, disaster response coordination, and the preservation of civil order, making the tower an indispensable lifeline in a crisis scenario. This specialized field requires an intimate understanding of dynamic structural behavior, advanced geotechnical analysis, and the unique response of slender, flexible structures—which communication towers inherently are—to the complex, multi-directional forces generated by ground motion, demanding a level of robustness far exceeding typical wind-load design criteria. This comprehensive exposition must flow seamlessly, beginning with the fundamental principles of earthquake engineering as applied to tall structures, moving through the specific design methodologies and material selection—emphasizing ductility and energy dissipation—that differentiate a seismic-resistant tower from a standard one, and concluding with the critical, long-term maintenance and inspection protocols required to ensure the tower’s readiness and integrity throughout its service life, all while maintaining a continuous, detailed, and non-formulaic narrative that captures the full depth of this vital engineering specialization.

🌐 The Imperative of Seismic Resilience: Why Standard Design is Insufficient

The design philosophy for standard communication towers is predominantly governed by static and dynamic loads imposed by wind and ice, factors that, while significant, fail to adequately capture the sudden, chaotic, and high-energy nature of seismic excitation, which introduces a fundamentally different set of structural demands that can lead to catastrophic failure if not explicitly addressed, necessitating the specialized discipline of seismic-resistant design. An earthquake does not apply a uniform lateral force like wind; instead, it generates complex ground accelerations that simultaneously move the tower’s base horizontally and vertically, causing the entire slender structure to respond dynamically by oscillating at its natural frequencies, often leading to a phenomenon known as resonance, where the ground motion frequency aligns with the tower’s natural frequency, dramatically amplifying the lateral displacements and internal forces far beyond the tower’s yield capacity, a failure mode particularly pronounced in tall, flexible monopole and lattice structures. Furthermore, the seismic forces are Inertial Forces, meaning the tower’s structural mass—including the steel structure itself, the concrete foundation, and the substantial antenna and equipment payload—acts as a driving force, resisting the rapid ground acceleration, thereby concentrating massive shear forces and bending moments at critical sections, particularly at the tower-foundation interface and at points where the structural cross-section changes abruptly, requiring a design focus not just on ultimate strength, but on the capacity for controlled, predictable energy absorption.

The standard wind design approach, which might rely on a structure reaching its maximum elastic limit, is wholly inadequate for seismic zones, where the cost of achieving full elasticity under extreme seismic events (a strategy known as Capacity Design) is often prohibitively high; consequently, seismic design adopts the philosophy of Ductility and Controlled Plasticity, recognizing that during a rare, severe earthquake (the Maximum Considered Earthquake, or $\text{MCE}$), the structure is permitted to undergo controlled, non-catastrophic yielding in pre-designated areas—known as Fuses or Energy Dissipation Zones—which absorb and dissipate the seismic energy through inelastic deformation, preventing the brittle fracture and total collapse that would otherwise occur, a sophisticated engineering trade-off that preserves the structural integrity and, critically, the operational continuity of the telecommunications equipment above. This fundamental shift from strength-only design to a Strength-and-Ductility design requires specialized material selection, meticulous detailing of connection points, and, most importantly, advanced Response Spectrum Analysis or Time History Analysis to accurately model the complex dynamic behavior of the tower under region-specific seismic wave inputs, thereby ensuring the structure is designed not just to stand, but to survive, yield predictably, and maintain the essential communication link when it is most desperately needed by the affected population and emergency services, a societal imperative that elevates seismic engineering to a moral and regulatory necessity in high-risk zones.

🏗️ Design Methodology and Material Selection for Energy Dissipation

The realization of a seismically resilient communication tower is achieved through a meticulous design methodology that focuses on strategically integrating ductility into the structural system, thereby enabling the controlled dissipation of seismic energy through plastic deformation at specific, repairable locations, a design philosophy that fundamentally influences the selection of materials, connection types, and the overall structural configuration. The process begins with rigorous Seismic Hazard Assessment, which defines the region-specific ground motion characteristics—peak ground acceleration ($\text{PGA}$), spectral acceleration ($\text{Sa}$), and soil types—which are mandated by standards like the ASCE/SEI 7 (Minimum Design Loads and Associated Criteria for Buildings and Other Structures) or regional seismic codes, transforming abstract geological risk into quantified engineering design parameters that define the required strength and ductility levels. For the structural steel itself, the material selection is paramount: conventional low-strength steels may lack the necessary uniform yielding capacity, while excessively high-strength steels can be too brittle, necessitating the use of High-Ductility Structural Steels (such as ASTM A992 or high-grade $\text{A572}$ with guaranteed low yield-to-tensile strength ratio), materials that are chemically composition-controlled to ensure a long, stable yield plateau before ultimate failure, thereby maximizing their capacity to absorb energy during the plastic deformation phase without fracturing, a metallurgical requirement that must be explicitly verified and documented through material testing.

The structural configuration often favors Truss Towers or specially designed Monopoles with Energy Dissipation Devices, moving away from standard lattice structures that can be prone to buckling in critical members. In truss designs, the principle of Strong Column/Weak Bracing is often employed, ensuring that the primary vertical legs (columns) remain elastic, while specific diagonal bracing members are intentionally designed to yield and buckle predictably, acting as the structural fuses that dissipate the seismic energy, requiring these bracing members to be meticulously detailed with robust connections that can sustain multiple cycles of plastic deformation without fracturing. For highly optimized monopole designs, where inherent flexibility is a challenge, the integration of specialized Base Isolation Systems or Viscoelastic Dampers at strategic points becomes a critical design element; base isolators decouple the tower from the severe horizontal motion of the ground, significantly lengthening the structure’s natural period and moving it away from the dominant frequencies of the earthquake, while viscoelastic dampers absorb kinetic energy and convert it into heat, effectively reducing the dynamic response and damping the oscillation, transforming the tower into an Active Seismic Resistor rather than a passive recipient of seismic energy. Furthermore, the design of the Tower-Foundation Interface and the Anchor Bolt Cluster must receive obsessive attention, as this is the zone where the massive inertial forces are transferred to the ground; utilizing deep pile foundations, robust concrete shear keys, and anchor bolts detailed to prevent brittle shear failure—often designed to yield in tension as a secondary fuse—ensures that the tower remains securely connected to the ground motion source without suffering a catastrophic base failure, thereby completing the layered, integrated seismic defense system that ensures both structural survival and continuous network functionality.

📐 Foundation Geotechnics and Structural Detailing: The Hidden Strength

The true seismic resilience of any tall structure, especially a communication tower with its high center of gravity and massive overturning moment potential, is largely dictated by the competence of its foundation and the surrounding soil-structure interaction (SSI), a geotechnical dimension that often represents the most critical and complex variable in the entire seismic design process, requiring specialized analysis beyond simple static bearing capacity calculations. The foundation must be designed not just to support the static vertical load, but to resist the enormous dynamic Overturning Moments and Shear Forces induced by the Maximum Considered Earthquake ($\text{MCE}$), demanding detailed Site-Specific Geotechnical Investigations—including boreholes, soil classification, and liquefaction potential assessment—to accurately determine the dynamic stiffness and damping characteristics of the underlying soil layers, information crucial for the Response Spectrum and Time History modeling. In soft or liquefiable soils, standard shallow mat or pier foundations are entirely inadequate, necessitating the use of deep foundation systems like Drilled Shafts (Caissons) or Driven Piles, which extend to competent bedrock or stable deep soil strata, ensuring that the foundation mass remains stable during severe ground shaking, thereby maintaining the tower’s rigid base connection and preventing excessive settlement or lateral displacement that would permanently compromise antenna alignment and structural integrity.

Equally critical is the meticulous Structural Detailing of every component, transforming the general design philosophy of ductility into tangible, manufactured reality, especially at the critical connection points where stress concentration is highest. In seismically designed truss towers, all bolted connections, particularly those involving the primary structural members and the energy-dissipating bracing, must utilize High-Strength, Pre-Tensioned Bolts (e.g., ASTM A325 or A490) with sufficient edge distances and redundancy to prevent premature bearing failure or bolt tear-out during the multiple cycles of inelastic deformation, a failure mode that can quickly lead to progressive collapse. Furthermore, the detailing must explicitly address the P-Delta Effects—the secondary moment created when the tower’s axial load ($P$) acts on the lateral displacement ($\Delta$) induced by the earthquake—a factor that can significantly destabilize a flexible structure and must be incorporated into the iterative design process, often requiring a slight increase in the structural member sizes or the inclusion of supplementary bracing to maintain stiffness under maximum expected deflection. Crucially, the Weld Detailing for tower members must conform to advanced welding codes (like AWS D1.1/D1.8), emphasizing full-penetration welds in critical load path areas and demanding the use of low-hydrogen filler metals and stringent Non-Destructive Testing (NDT)—such as Ultrasonic Testing (UT) and Magnetic Particle Testing (MPT)—to ensure the weld metal possesses the necessary strength and, critically, the required ductility to yield along with the base material without fracturing, guaranteeing that the designed “fuse” function of the yielding members is not undermined by brittle weld failure, thereby showcasing that seismic resilience is achieved through a painstaking attention to detail, from the geology miles below the surface to the smallest weld bead in the structure.

⚡ Operational Resilience and Equipment Survival: The Communication Lifeline

While the structural design ensures the tower remains standing after the $\text{MCE}$, the ultimate goal of a seismic-resistant communication tower is Operational Continuity, meaning the sensitive electronic equipment and the transmission links must survive the seismic event and remain functional, a challenge that requires integrating the structural engineering effort with meticulous equipment mounting, power management, and antenna system design, ensuring the entire system acts as a resilient unit. The forces imparted to the antennas, Remote Radio Heads ($\text{RRHs}$), and equipment cabinets mounted on the tower can be significantly amplified due to the tower’s dynamic response; consequently, the Equipment Mounting Systems must be designed with specialized Seismic Bracing and Vibration Isolators that dampen the tower-induced accelerations before they reach the critical components, preventing damage to sensitive circuit boards, fiber optic interfaces, and critical connectors. All antennae, particularly the highly directional $\text{mmWave}$ and microwave backhaul dishes, must be secured with High-Strength Clamping Systems that are capable of maintaining their precise azimuth and elevation alignment during and immediately after the seismic event, as even minor rotational shifts can render the transmission links inoperable, thus requiring the use of specialized, oversized mounting hardware designed for high-shear resistance, well beyond standard wind load practice.

Furthermore, the On-Ground Equipment Shelter and its contents—the Base Transceiver Station ($\text{BTS}$), power systems, and cooling units—must be treated with equal seismic rigor. The shelter itself is often designed as a Seismically Qualified Structure, secured to the foundation with shear keys and robust anchor bolts to prevent sliding or overturning, and all internal racks, battery banks, and generators must be mounted with Seismic Restraints and Anchors, ensuring they cannot tip over or collide with each other during ground shaking, a failure mode that is surprisingly common and often leads to power system or $\text{BTS}$ damage. Critical to operational continuity is the Power System Resilience, requiring generators and battery banks to be seismically rated and protected to ensure the necessary backup power is available immediately post-earthquake when the grid infrastructure is almost certain to fail; the fuel lines and electrical conduits connecting the shelter to the tower must incorporate Flexible Connectors and sufficient slack to accommodate differential movement between the tower foundation and the shelter foundation without severing the power, grounding, or data connections. The ultimate measure of success is the Post-Earthquake Functional Test, a procedure that should be incorporated into the maintenance protocol, ensuring that the network can be rapidly brought back online or, ideally, remains operational throughout the event, confirming the tower’s successful transformation from a mere structural support into a certified, highly resilient communication lifeline capable of fulfilling its essential public service role during the most extreme civil emergencies.

🛠️ Post-Construction Maintenance and Inspection: Sustaining Seismic Readiness

The design and construction of a seismic-resistant communication tower represent only the beginning of its lifecycle; the long-term, sustained assurance of its readiness to survive a future earthquake relies entirely on a rigorous and highly specialized Post-Construction Maintenance and Inspection Program, a critical operational phase that ensures the integrity of the initial design philosophy is preserved against the constant degradation of time, corrosion, and operational stress. Standard maintenance procedures, focused primarily on coating renewal and visual inspection, are insufficient for seismic readiness, which demands the adoption of a Periodic, Detailed Seismic Inspection Protocol typically conducted by certified structural engineers at intervals mandated by the local seismic hazard level, where the focus shifts from general fatigue to the specific integrity of the structural fuses and critical connections designed to absorb seismic energy. This specialized inspection must include Non-Destructive Testing (NDT) on critical areas, particularly the tower-to-foundation connection, all gusset plates, and the ends of the deliberately designed yielding members (bracing); technicians must utilize Magnetic Particle Testing (MPT) or Dye Penetrant Inspection (DPI) to check for micro-cracks near weld toes or bolt holes, hairline fractures that could rapidly propagate into full failure during an earthquake, defects that are often invisible to the naked eye but represent a severe compromise of the intended ductility.

A critical aspect of sustaining seismic readiness is the Monitoring and Maintenance of Specialized Energy Dissipation Devices, such as viscoelastic dampers or base isolators, which require a separate, highly specialized maintenance schedule; technicians must regularly check the physical condition of the damper’s material for signs of degradation (such as hardening or cracking) and verify that the base isolation system’s bearings or sliding surfaces are free of debris and functioning correctly, ensuring the system remains responsive and capable of absorbing the massive kinetic energy as designed, as a failure in these devices can negate the entire seismic defense strategy. Furthermore, the integrity of the Grounding and Lightning Protection System requires enhanced vigilance, not just for electrical safety, but for its role in preventing the catastrophic ignition of nearby equipment during a lightning strike which, if combined with seismic damage, presents an unmanageable crisis, thereby requiring continuous monitoring of ground resistance values. Finally, the inspection must specifically verify the integrity and tension of all Equipment Seismic Restraints within the shelter and on the tower itself, ensuring that none of the vital anchors, clamps, or specialized mounting hardware have been compromised or removed during routine maintenance or equipment upgrades, as the accidental removal or substitution of a seismic-rated bolt with a non-seismic equivalent can destroy the system’s resilience. The long-term maintenance of a seismic-resistant communication tower is thus a high-stakes, specialized commitment to preserving the original engineering trade-off of strength and ductility, ensuring that the critical structural and electronic components are in a constant state of operational readiness to serve as the region’s communication lifeline when the ultimate test of the earthquake inevitably arrives.

📋 Technical Design and Maintenance Summary for Seismic Towers

| Parameter | Structural Standard | Seismic Design Principle | Typical Material/Component | Requirements/Target |

| Governing Standard | Structural Load | TIA-222 (Communications), ASCE/SEI 7 (Seismic) | High-Strength Structural Steel (A572 Gr. 50/65) | Design for $\text{MCE}$ (Maximum Considered Earthquake) loads. |

| Design Philosophy | Seismic Resistance | Ductility and Controlled Plasticity | Ductile Steels (Low $\text{Y/T}$ Ratio), Energy Dissipation Devices | Prevent Collapse; Ensure Operational Continuity. |

| Structural Fuses | Energy Dissipation | Strong Column / Weak Bracing | Designed-to-Yield Bracing Members | Bracing must sustain multiple cycles of plastic deformation without fracture. |

| Foundation | Geotechnical | Liquefaction and Overturning Resistance | Drilled Shafts/Piles, Seismic Shear Keys | Foundation must remain stable and prevent excessive settlement/rotation. |

| Key Detailing | Connections | Prevention of Brittle Failure | High-Strength Pre-Tensioned Bolts (A325/A490), Full Penetration Welds | Connections must be stronger than the members they join (Capacity Design). |

| Equipment Survival | Dynamic Response | Vibration Damping and Isolation | Seismic Bracing, Vibration Isolators, Flexible Connectors | Equipment ($\text{BTS/RRH}$) must remain anchored and functional post-event. |

Maintenance and Inspection Requirements

| Inspection Domain | Focus Area | Required Testing Method | Maintenance Interval (Typical) | Critical Goal |

| Structural Integrity | Critical Welds and Connections, Yield Zones | UT (Ultrasonic Testing), MPT (Magnetic Particle Testing) | Biennial (or per local seismic code) | Check for micro-cracks and fatigue in potential yield areas. |

| Energy Dissipation | Dampers, Base Isolators, Bearings | Visual check for damage, Material Hardness/Degradation Test | Annual/Biennial (Specialized Protocol) | Ensure isolation system remains functional and responsive. |

| Anchorage | Anchor Bolts, Shelter Anchors, Equipment Racks | Torque Verification, NDT on Anchor Welds | Annual/Post-seismic event | Prevent tipping or sliding of tower base and equipment. |

| Coating/Corrosion | Coating Thickness, Stress Concentration Points | DFT Meter, Visual/DPI Inspection | Annual | Prevent loss of cross-section due to rust, which reduces ductility. |

| Operational Readiness | Power, Data, Antennas | Earth Resistance Test, Alignment Check ($\text{AAT}$), Functional Test | Semi-Annual | Guarantee power availability and communication link integrity. |

💡 Conclusion: Engineering for the Unthinkable

The seismic-resistant communication tower represents the highest standard of structural engineering applied to critical infrastructure, moving far beyond the conventional safety margins of wind and ice loads to directly confront the unpredictable and devastating forces of a major earthquake. The design success hinges on a calculated, intentional strategy of ductility, achieved through the meticulous selection of high-ductility steel, the strategic placement of structural fuses in bracing members, the use of advanced energy dissipation systems, and the robust detailing of connections and foundations that ensure the entire system yields predictably without collapsing. Post-construction, this life-saving design is sustained by a specialized maintenance program, focused on NDT verification, monitoring of specialized dampers, and ensuring the seismic readiness of all electronic and power equipment. Ultimately, the seismic-resistant communication tower is a tangible commitment to national resilience, guaranteeing that when the ground shakes and conventional systems fail, the essential communication lifeline remains intact, providing the critical foundation for recovery and coordination in the face of the unthinkable.

Would you like me to elaborate on the specific material selection criteria for high-ductility structural steel, including the role of the yield-to-tensile ratio, or perhaps detail the Soil-Structure Interaction (SSI) modeling process in seismic design?