Polygonal Steel Distribution Poles for power transmission

October 3, 2025

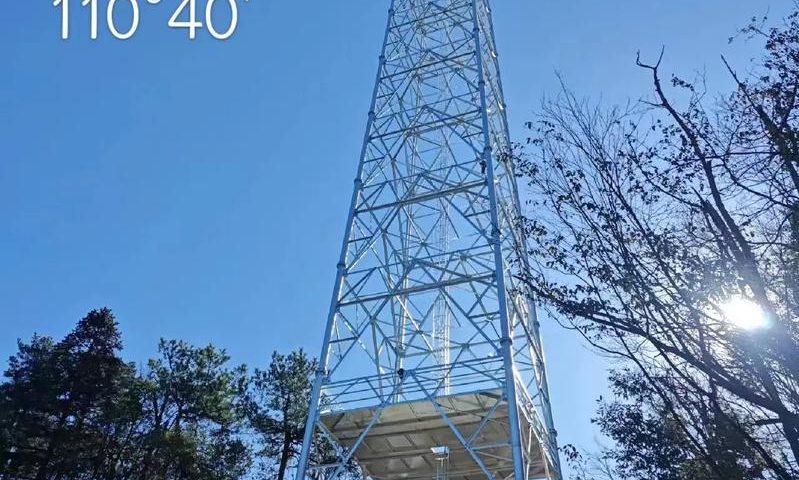

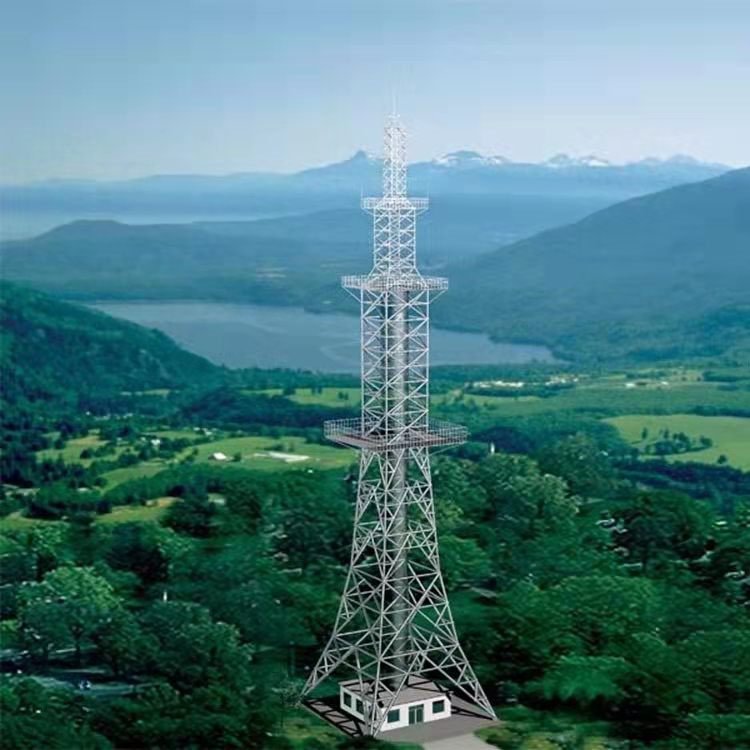

Technical Specifications for Angular Lattice Steel Transmission Towers

October 26, 2025Unpacking the Differences Between Self-Support Tower and Guyed Towers

The Architectural Divide: Unpacking the Differences Between Self-Support and Guyed Communication Towers

The modern world is interconnected by a vast, silent network of information, and the most visible symbols of this connectivity are the towering structures that hold our antennas and broadcast equipment aloft. These monoliths of steel and concrete, vital for telecommunications, radio, and television broadcasting, fall broadly into two primary structural categories: self-support towers and guyed towers. While both serve the fundamental purpose of achieving necessary elevation, their designs, structural mechanics, economic profiles, and suitability for different environments are fundamentally divergent. Understanding this architectural divide is crucial for engineers, infrastructure planners, and anyone interested in the physical backbone of the digital age. The differences extend far beyond a casual visual inspection, touching upon critical aspects of stability, land use, construction logistics, and long-term maintenance costs.

Foundational Concepts: Defining the Structures

At the core of the distinction lies the method by which each structure achieves lateral stability, the crucial ability to resist forces like wind and seismic events.

A self-support tower, often referred to as a lattice tower, a free-standing tower, or a truss tower, is a structure that stands upright entirely by virtue of its own internal rigidity and the strength of its foundation. These structures are typically built using a steel lattice framework, forming a wide base that tapers towards the top. The load-bearing members are arranged in a triangular or square cross-section, relying on the geometric principle of triangulation to distribute compressive and tensile stresses. The tower’s stability is an intrinsic property of its geometry and mass; it does not require any external wires or supports to remain vertical. Think of it as a giant, three-dimensional steel column anchored firmly into the ground.

In stark contrast, a guyed tower is a slender mast whose vertical stability is entirely dependent on a system of tensioned cables, known as guy wires, that extend diagonally from the tower body to anchor points in the ground. Without these guy wires, the mast would be unstable and collapse. The mast itself is primarily designed to handle vertical loads (the weight of the equipment and the mast itself) and the horizontal forces induced by the wind. The guy wires, arranged in multiple levels and directions (typically three sets, apart, at each level), provide the massive lateral resistance required to keep the slender mast erect and prevent buckling. This fundamental dependence on external support is the single most defining characteristic that separates the two types of structures.

The Crucial Difference in Structural Mechanics and Loading

The varying approaches to stability result in drastically different load paths and stress distributions within the two tower types. This is where the engineering science truly diverges.

Self-Support Tower Mechanics

In a self-support tower, the wind forces acting on the antennas and the tower structure itself are resolved directly through the lattice framework down into the base. The legs of the tower experience massive, varying forces: one side of the tower will be under compression (pushed down) while the opposing side is under intense tension (pulled up) due to the overturning moment created by the wind. The foundation must, therefore, be robust enough to handle both significant compressive loads and a substantial uplift force on the windward side.

The sheer size and strength of the base, often forming a square or triangular footprint that can be many meters wide, is what resists the moment. The structure’s rigidity is a function of the massive bending moment it is designed to withstand. This requirement for a large, strong base and heavy members throughout the structure means that self-support towers are inherently heavier and require deeper, more complex foundations than guyed towers of the same height. The complexity of analyzing the countless truss members under various loading conditions, though standardized by codes, is a testament to the intricate mechanical work being performed by the steel skeleton. Furthermore, in taller self-support towers, the shear forces at the base are considerable, requiring substantial bolting and concrete work to ensure integrity.

Guyed Tower Mechanics

The structural life of a guyed tower is one of tension and compression. The slender mast is essentially a column that is supported laterally at various points by the guy wires. When wind hits the tower, the mast tends to deflect. This deflection is countered by the tension in the guy wires. The windward guy wires may become slack, while the leeward guy wires take on a massive increase in tension, effectively pulling the tower back into alignment.

Crucially, the mast itself is largely relieved of the enormous bending moment that dominates the self-support tower design. The guy lines transfer the horizontal wind forces into tension loads at their anchor points in the ground. This means the mast can be significantly lighter and narrower than a self-support tower of equivalent height. However, the vertical loading on the foundation is still high, as the guy wires also pull down on the mast top, adding to the compressive force. The primary engineering challenge for the mast is preventing column buckling between the guy attachment points, which necessitates a very straight, accurately manufactured structure. The foundation for the mast is primarily designed to handle high compressive and shear forces, while the separate guy anchor foundations must be engineered specifically to resist extreme uplift (tension) forces, often involving massive concrete blocks or specialized deep anchors. The static and dynamic analysis of guyed towers must also account for the complex interaction of the mast’s natural vibration frequencies with the damping and spring-like effects of the tensioned guy wires, a factor that is less pronounced in the rigid self-support structure.

Spatial Footprint and Land Use: The Area Conflict

One of the most immediate and tangible differences between the two designs is the land required for their installation. This is often the deciding factor in urban and densely populated areas.

Self-Support Tower Footprint

The footprint of a self-support tower is defined solely by the area of its base, which is relatively small. A typical self-support tower’s base might occupy a square of, say, at ground level, though this varies significantly with height and wind load. All structural elements and foundations are contained within this small area. This characteristic makes the self-support tower the undisputed champion for urban environments, atop buildings, or on small, constrained parcels of land where space is a premium and land acquisition costs are prohibitive. The absence of external lines means that the area surrounding the tower is largely unobstructed and can often be repurposed for other uses, such as parking or small utility buildings, right up to the perimeter fence.

Guyed Tower Footprint

The guyed tower, by necessity, demands a substantially larger right-of-way. The guy wires must extend out from the mast at a shallow angle to provide effective lateral stability. For a very tall tower, the anchor points for the lowest set of guys can be located hundreds of meters away from the mast base. The general rule of thumb dictates that the anchor radius can be anywhere from to

times the height of the tower. For example, a

guyed mast might require an operational radius of

to

for the guy anchors, resulting in a land area requirement that is orders of magnitude greater than that of a self-support tower. While the land directly under the guy wires can sometimes be used for low-profile purposes (like agriculture), the area must be kept clear of tall structures, and vehicular access is required for maintenance, making the land significantly restricted. This expansive footprint makes guyed towers impractical and generally uneconomical for metropolitan settings but ideal for large, remote, and rural sites where land is abundant and inexpensive.

Economic Analysis: Initial Cost vs. Long-Term Expense

The cost comparison is not simply a matter of the initial capital outlay but requires a detailed life-cycle cost analysis that incorporates construction, maintenance, and potential future modifications.

Initial Capital Cost (CAPEX)

For a given height, a guyed tower will almost always have a lower initial material and fabrication cost for the mast itself. Because the mast is relieved of most of the bending moment, it uses less steel and can have a much lighter cross-section.

The self-support tower requires significantly more steel to build the rigid lattice structure and a much more extensive and heavier foundation to resist the uplift and enormous overturning moment. Therefore, the total initial CAPEX for a self-support tower is typically times higher than a comparably sized guyed tower.

However, the analysis must factor in the land cost. In high-cost urban areas, the lower land acquisition cost for a small-footprint self-support tower can quickly offset its higher structural cost, rendering it the cheaper overall solution. In rural settings, the lower cost of the guyed structure and land makes it the clear economic winner.

Maintenance and Operational Expense (OPEX)

Maintenance is where the tables often turn, and the simplicity of the self-support tower begins to yield long-term savings.

Self-Support Tower Maintenance: Maintenance for self-support towers is relatively straightforward. It involves periodic inspections of the steel members for corrosion, checking the structural bolts for tension, and maintaining the protective paint system. Access is vertical, using a ladder or climbing system on the tower itself. The main structural elements are static, meaning fewer moving parts to worry about.

Guyed Tower Maintenance: Guyed towers have a critical additional maintenance item: the guy wires. These wires are under constant, high tension and are subject to fatigue, corrosion, and dynamic loading (vibration). They must be regularly inspected for wear, strand breakage, and, most importantly, their tension must be periodically measured and adjusted (re-tensioned) to ensure the mast remains plumb and the stress distribution is correct. Anchor points also require inspection for stability. This specialized, regular, and critical maintenance of the guy system adds a significant and perpetual cost to the OPEX of a guyed tower. Furthermore, if a single guy wire or anchor fails, the catastrophic collapse of the entire structure is imminent, making routine maintenance not just cost-saving, but safety-critical. The replacement of entire sets of guy wires is a major capital expense that must be factored into the life-cycle analysis, an expense a self-support tower simply does not have.

Construction and Installation Logistics

The methods used to erect the two types of structures are also dramatically different, impacting project timelines, equipment needs, and safety protocols.

Self-Support Tower Construction

Self-support towers are typically constructed piece-by-piece, or in small, pre-assembled sections, using a crane or a specialized climbing derrick (a gin pole) that is anchored to the completed portion of the tower and progressively lifts the next section into place. Construction is a vertical operation that proceeds upward, usually starting with the largest, heaviest base section. This method requires a relatively small construction laydown area and is well-suited for confined sites. The entire assembly process is contained within the footprint and the immediate surrounding area. The challenge lies in lifting heavy, massive sections to great heights and ensuring the precise alignment of the complex bolted connections.

Guyed Tower Construction

Guyed towers are often installed using one of two primary methods. For shorter masts, the entire structure may be assembled on the ground and then “walked up” (or hinged) into position using a powerful crane or a winch system, pivoting on a base hinge. For taller structures, a gin pole is used in a similar fashion to self-support construction, but the pieces are lighter and more manageable. The major logistical difference is the complex, concurrent installation of the guy anchor foundations and the precise laying out and tensioning of the multiple levels of guy wires. The construction process is heavily dependent on the weather, as high winds can make the initial tensioning and alignment of the slender mast dangerous or impossible. The large construction laydown area required for the sprawling anchor points and the cable reeling is a necessity.

Environmental and Aesthetic Considerations

In the modern planning environment, the impact of large structures on the surrounding landscape and community cannot be ignored.

Aesthetic Impact

Self-Support Towers: The rigid, lattice design often gives self-support towers a more industrial or technical aesthetic. While some are architecturally celebrated (like the Eiffel Tower), they are generally perceived as a heavy, imposing presence due to their wide base.

Guyed Towers: The slender mast profile of a guyed tower can appear less intrusive against the skyline, giving it a more elegant or minimalist look, particularly from a distance. However, the numerous guy wires, visible on the ground and sometimes glinting in the sun, can be seen as an eyesore or a hazard to aircraft, necessitating painting or the use of marker balls on the cables.

Environmental Impact

The primary environmental difference is the habitat impact. The small, concentrated foundation of a self-support tower disturbs a minimal land area. The extensive network of guy wires and anchor points for a guyed tower, however, disrupts a much larger swath of land, which can be an ecological concern in sensitive areas. Furthermore, the guy wires themselves pose a significant, well-documented hazard to low-flying aircraft and migratory birds, a factor that requires careful mitigation and planning in certain flight paths or wildlife corridors.

Capacity, Rigidity, and Future Proofing

The intended use and the possibility of future expansion heavily influence the choice of tower.

Load and Capacity

Self-Support Towers: These structures inherently offer higher load capacity and greater structural rigidity. Their wide base and heavy-duty construction allow them to support a much greater volume and weight of antennas, microwave dishes, and accessory equipment. Furthermore, their superior stiffness means that they experience less sway and deflection under wind loading. This is critically important for microwave relay systems which require extremely precise antenna alignment (often within a fraction of a degree) to maintain line-of-sight communication. The rigidity of the self-support tower makes it the mandatory choice for heavily loaded sites, co-location facilities, and major microwave backbone links.

Guyed Towers: While a well-designed guyed mast can be extremely tall (holding the record for the tallest structures ever built), their slenderness means they have a lower inherent load capacity and are prone to greater deflection under wind. This sway, though designed for, can be detrimental to the performance of highly directional microwave dishes. They are best suited for lighter loads, such as single-operator cellular antennae, FM/TV broadcast antennas, or general-purpose telecommunications where precision alignment is less critical than simple height and coverage area.

Future-Proofing and Modification

The design of a self-support tower generally allows for easier future modifications and co-location. Adding new antenna platforms or increasing the diameter of the antennas is often possible by verifying the residual capacity of the existing structural members. The structure is inherently modular in its capacity.

A guyed tower has less built-in capacity for expansion. Adding significant load requires re-analyzing the entire guy system, and often, the only safe way to increase capacity is to add new guy levels or replace the existing guy wires with thicker, stronger ones—a major, disruptive, and costly operation. Co-location of multiple operators on a single guyed mast is often a greater engineering challenge than on a self-support tower.

Summary of Deployment Scenarios

The choice between a self-support and a guyed tower is, therefore, a multi-faceted decision matrix based on a precise understanding of the project’s constraints and goals.

| Feature | Self-Support Tower | Guyed Tower |

| Stability Mechanism | Intrinsic rigidity and wide base (Internal) | Tensioned external guy wires (External) |

| Footprint/Land Use | Very small, concentrated area | Very large, sprawling area for anchors |

| Initial Cost (CAPEX) | High (due to more steel and heavy foundation) | Low (lighter mast and foundation) |

| Maintenance (OPEX) | Lower (routine inspection/paint) | Higher (critical, regular guy tensioning/replacement) |

| Load Capacity | High (Excellent rigidity for microwave) | Lower (prone to more sway) |

| Ideal Environment | Urban, constrained, co-location heavy sites | Remote, open, rural sites with cheap land |

| Risk Profile | Lower risk of catastrophic failure from maintenance lapse | Higher risk of catastrophic failure from guy wire/anchor failure |

The difference between the self-support tower and the guyed tower is a classic engineering trade-off. The self-support tower offers long-term predictability, high load capacity, and minimal land impact at the expense of a higher initial capital outlay. The guyed tower offers unrivaled height potential and a low initial construction cost but demands a massive land area and requires a perpetual, specialized maintenance budget for its critical guy system. As telecommunications needs continue to evolve, with an increasing demand for co-location and rapid deployment in diverse environments, both structural solutions will continue to play indispensable roles, each optimized for the specific challenges of its operating environment. The final decision always balances the upfront budget, the lifetime operational expense, the available land, and the specific performance requirements of the transmission equipment the tower is designed to serve.