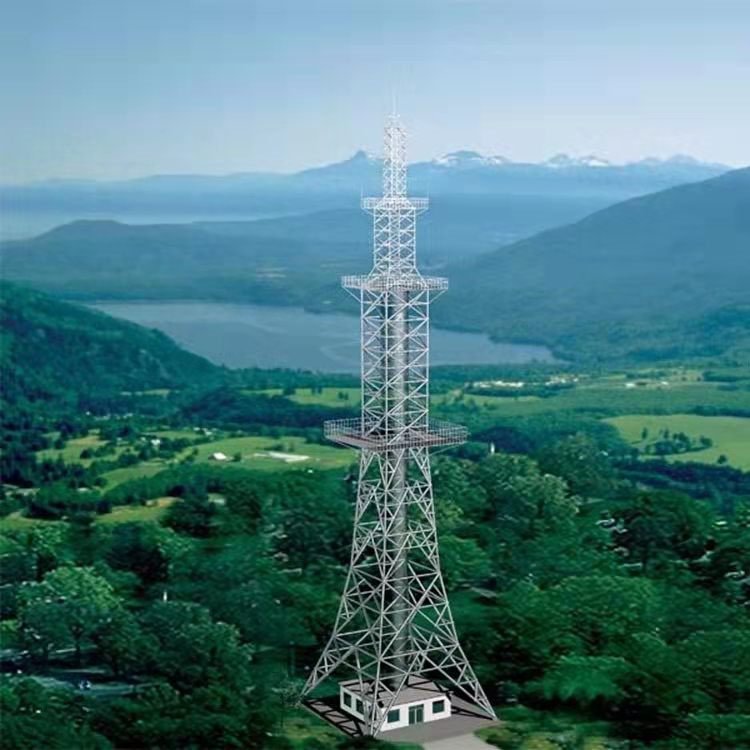

330kV Electric Transmission Line Tower

January 1, 2026

Study on Wind Load Coefficients of Angle Steel Transmission Tower Cross-arms under Skewed Wind Angles: A Technical Analysis

January 11, 2026Key Factors Affecting Life Cycle Cost (LCC) of Telecom Towers: Structural & Environmental Hierarchy

In contemplating the structural evolution and economic sustainment of telecommunication infrastructure, specifically the life cycle cost (LCC) of communication towers, one must first engage with the sheer complexity of environmental and mechanical interdependencies that dictate the movement of capital over a thirty-to-fifty-year horizon. We are not merely looking at a pile of galvanized steel anchored in concrete; rather, we are analyzing a dynamic system subjected to stochastic wind loading, electrochemical degradation, and the relentless pressure of technological obsolescence which necessitates periodic structural hardening. The “Inner Monologue” of a lifecycle analysis begins with the realization that the initial capital expenditure (CAPEX), while the most visible, is often eclipsed by the cumulative operational expenditure (OPEX) and the eventual decommissioning costs, creating a multi-dimensional optimization problem that requires us to move beyond simple linear depreciation. When we begin to identify the factors affecting LCC, we must look at the macro-environmental stressors—ranging from the corrosivity of the local atmosphere (ISO 9223 categories) to the seismic activity of the terrain—and then zoom in on the micro-structural choices, such as the bolt-to-weld ratio in lattice joints or the specific gravity of the zinc coating, all of which act as variables in a long-term economic equation where the goal is to minimize the Net Present Value (NPV) of the total ownership cost.

The identification of these cost drivers starts with the “Design and Materialization Phase,” which sets the trajectory for the entire lifespan of the tower. If we opt for high-strength Q420 steel over the more common Q235B, we are essentially trading a higher material cost today for a reduction in total structural weight and foundation volume, which in turn reduces transport costs and installation time, yet this decision also alters the tower’s natural frequency and its sensitivity to vortex-induced vibrations. We have to think about the “Maintenance Gradient,” where a decision to use a lower-grade hot-dip galvanization might save $500 during the fabrication stage but results in an exponential rise in recoating costs fifteen years later when the zinc-iron alloy layer begins to delaminate in a C4-corrosivity environment. This brings us to the first tier of our hierarchy: the Fundamental Structural Variables, which encompass the geometry of the tower (monopole vs. lattice vs. guyed mast), the material properties, and the foundation type, each of which establishes the “Floor” of the maintenance budget.

| Cost Category | Influence Factor | Parameter Specification / Metric | Impact on LCC |

| Direct CAPEX | Structural Steel Grade | Q235B, Q345B, Q420 (ASTM A572) | High (Initial weight/stiffness) |

| Indirect CAPEX | Terrain Accessibility | Coastal, Mountainous, Urban, Remote | Medium (Logistics & Installation) |

| Operational (OPEX) | Corrosion Protection | Hot-dip Galv (85-100μm) vs. Thermal Spray | High (Long-term surface integrity) |

| Structural OPEX | Loading Capacity Reserve | Wind Speed (V=25-50m/s) / Antenna Area | Medium (Hardening for 5G/6G) |

| Decommissioning | Recyclability | Steel scrap value vs. Concrete removal | Low (Terminal salvage value) |

As our internal logic flows into the Operational and Environmental Tier, we must consider the “Invisible Costs” of site occupancy and energy consumption, though for a passive structure like a tower, the energy aspect is often localized to the aviation obstruction lighting or the cooling of base stations at the tower foot. However, the true cost driver in this middle hierarchy is the “Dynamic Load Adaptation.” Telecommunications is an industry of rapid cycles; a tower designed for 2G/3G loading may find itself structurally inadequate for the heavy Active Antenna Units (AAUs) required by 5G or future 6G deployments. This “Obsolescence Risk” is a major LCC factor that is often misclassified as a maintenance issue when it is actually a strategic design flaw. If the hierarchy is not correctly established—placing “Adaptability” as a secondary-tier factor—the operator faces a “Replacement Cost” rather than an “Upgrade Cost,” which can be ten times more expensive. We must mathematically model the fatigue life of the steel under fluctuating wind pressures, using the Miner’s Rule for cumulative damage, while simultaneously accounting for the “Economic Fatigue” caused by increasing lease rates for the land beneath the structure.

The Management and Terminal Tier occupies the highest level of our hierarchical structure, focusing on the systemic decisions that govern the transition from “Active Service” to “Disposal.” Here, the identification of factors shifts from the physical to the administrative: the frequency of structural health monitoring (SHM) intervals, the insurance premiums associated with high-risk wind zones, and the “Deconstruction Methodology.” A monopole in an urban center has a very different terminal cost profile than a lattice tower in a rural field; the former requires specialized cranes and traffic management, while the latter can often be dismantled with minimal site impact. This consciousness leads us to the “Salvage Value” paradox—the steel in a tower represents a significant amount of embodied energy and material that can be recycled, and at the end of its life, the price of scrap steel can act as a partial rebate on the decommissioning cost. Therefore, a comprehensive LCC model must be sensitive to global commodity price fluctuations, recognizing that a tower is not just a service-providing asset but also a localized store of high-quality industrial metal.

To synthesize these flowing ideas into a scientific framework, we propose a Hierarchical Analytical Structure for 330kV and communication towers alike, where the “Top Level” is the Strategic Cost Objective, the “Middle Level” consists of the Technical and Environmental Constraints, and the “Base Level” comprises the granular Material and Execution variables. We must realize that every bolt tightened during construction carries a labor cost that is compounded by the “Inspection Debt” it creates for the next forty years. By using a “Multi-Criteria Decision Making” (MCDM) approach integrated with the “Life Cycle Impact Assessment” (LCIA), we can finally begin to see the tower not as a static object, but as a living, degrading, and evolving participant in the global digital economy. The depth of this analysis reveals that the most “expensive” tower is rarely the one with the highest price tag at the factory gate, but the one whose design failed to anticipate the corrosive breath of the ocean or the heavy weight of the next technological revolution.

In the profound depths of this technical introspection, we must move beyond the static identification of variables and begin to synthesize the Hierarchical Mapping of Life Cycle Cost (LCC) through a lens of recursive engineering—essentially asking how each tier of the hierarchy feeds back into the others over a multi-decadal timeline. When we look at the Tier I: Primary Structural Determinants, we are engaging with the “Genetic Code” of the tower; the choice between a four-legged lattice structure and a tapered monopole isn’t just an aesthetic or spatial decision, it is a commitment to a specific aerodynamic profile and a predictable failure mode. In the consciousness of a structural analyst, the lattice tower is a symphony of redundant load paths, where the LCC is heavily weighted toward the initial labor of bolting thousands of components, whereas the monopole represents a “low-entropy” design with fewer parts but higher sensitivity to Second-Order Effects like the P-Delta moment. If we contemplate the foundation—the literal anchor of the LCC—we see that the “Subsurface Risk” is perhaps the most volatile factor in the entire hierarchy. A miscalculation in the soil’s bearing capacity or the groundwater’s acidity doesn’t just increase CAPEX; it creates a “Structural Debt” where the foundation might require expensive chemical grouting or micro-piling twenty years into the lifecycle, a cost that is almost impossible to recover through operational efficiencies.

Moving into the fluid complexity of Tier II: Environmental and Operational Oscillations, the internal monologue shifts toward the relentless process of entropy. We must analyze the “Corrosion-Fatigue Synergism.” In a coastal environment, the salt-laden atmosphere doesn’t just sit on the surface; it penetrates microscopic cracks in the galvanization caused by the cyclical wind loading. This is where the hierarchy becomes truly scientific: the Corrosivity Category (C1 to CX) dictates the “Maintenance Interval Curve.” For a 330kV transmission tower or a high-load comms mast, the difference between a 15-year and a 25-year painting cycle can represent a 40% swing in the total NPV of the asset. We also have to think about the “Technological Drag” of the 5G/6G transition. A tower’s “Structural Reserve” is its most valuable intangible asset. If the hierarchy of cost factors doesn’t prioritize Modular Scalability, the operator is forced into a “Brownfield Replacement,” which involves not only the cost of a new structure but the “Service Interruption Penalty” and the massive logistical headache of migrating live RF equipment under strict “No-Downtime” mandates.

As we reach the Tier III: Management and End-of-Life (EoL) Optimization, we enter the realm of strategic asset management and the “Circular Economy” of steel. The identification of terminal factors requires us to look at the “Decommissioning Liability.” A tower in a remote, high-altitude location has a terminal cost that might actually exceed its original installation cost due to the requirement for heavy-lift helicopters and specialized environmental remediation teams. However, if we’ve designed the tower using high-strength, recyclable micro-alloyed steels, the “Salvage Credit” can act as a significant hedge. We must also consider the “Regulatory Compliance Inflation”—the fact that safety standards (such as TIA-222-H or Eurocode 3) inevitably become more stringent over time. A tower that met the “Life Safety” criteria in 2005 might require a “Retroactive Hardening” in 2030 just to remain legal, even if it is physically sound. This “Legislative Volatility” is a Tier III factor that many LCC models fail to quantify, yet it represents a massive potential spike in the long-term cost profile.

| Hierarchical Level | Factor Category | Specific Influence Parameter | Mathematical/Scientific Relation |

| Level 1 (Core) | Physical Configuration | Slenderness Ratio ($\lambda$) | $LCC \propto \text{Mass} \times \text{Installation Complexity}$ |

| Level 2 (Dynamic) | Environmental Stress | Chloride Deposition Rate | $Rate \propto \text{Distance from Coast} \times \text{Humidity}$ |

| Level 2 (Tech) | Load Adaptation | Surface Area of AAUs ($E_p$) | $Stress \propto (V^2 \times C_d \times A)$ |

| Level 3 (Strategic) | Economic Policy | Discount Rate ($r$) | $NPV = \sum [C_t / (1+r)^t]$ |

| Level 3 (Terminal) | Salvage Physics | Steel Grade Purity | $Credit = \text{Market Price} – \text{Demolition Energy}$ |

In the final synthesis, the technical analysis of a communication tower’s life cycle cost reveals a structure of “Nested Risks.” The hierarchy is not a static list but a cascading series of dependencies where a 1% saving in the material grade at Level 1 can trigger a 20% increase in the maintenance frequency at Level 2, eventually leading to a premature EoL event at Level 3. To truly master the LCC, we must adopt a Stochastic Life Cycle Assessment (SLCA), acknowledging that while we can predict the gravity loads with 99% accuracy, the wind gusts and the technological shifts of the next century are probabilistic events. The “Scientific Depth” of our product lies in its ability to absorb these shocks—providing a structural and economic “Buffer” that ensures the backbone of the digital grid remains standing, even when the economic and environmental climates are in a state of total flux.