Study on Wind Load Coefficients of Angle Steel Transmission Tower Cross-arms under Skewed Wind Angles: A Technical Analysis

January 11, 2026

High-Strength Wind-Resistant Power Transmission Towers – Research and Development

January 31, 2026Tower Steel Structure Rust Detection Technology: A Comprehensive Analysis

1. Introduction

1.1 Research Background and Significance

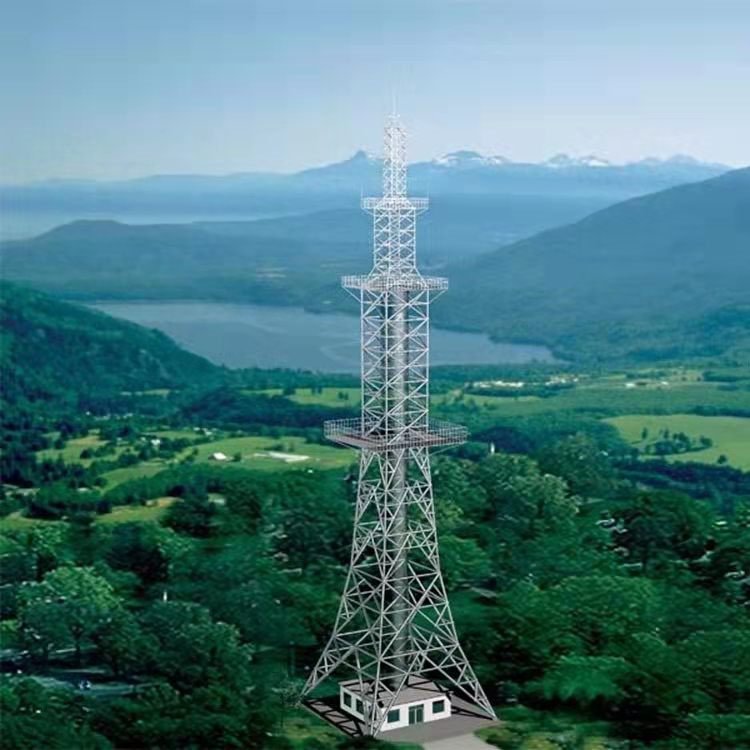

In modern infrastructure, tower steel structures play a crucial role and are widely applied in various fields such as power transmission, communication, and transportation. For instance, in the power industry, high – voltage transmission tower steel structures are responsible for safely and stably delivering electricity over long distances. In the communication sector, communication tower steel structures support antennas, ensuring the normal operation of wireless communication networks.

However, these tower steel structures are constantly exposed to harsh natural environments, including moisture, oxygen, and various chemical substances in the air and soil. As a result, corrosion is a common and serious problem. Rust not only affects the appearance of the steel structure but also significantly threatens its safety and service life. Once corrosion occurs, the mechanical properties of the steel, such as strength and ductility, will gradually decline. If left undetected and untreated for a long time, it may lead to the structural failure of the tower, which could cause power outages, communication disruptions, and even pose a serious threat to public safety.

Therefore, the research on rust detection technology for tower steel structures is of great practical significance. Precise and timely detection of rust can enable maintenance personnel to take corresponding measures in advance, such as anti – corrosion treatment, part replacement, etc., to ensure the safe operation of tower steel structures and extend their service life, thereby reducing maintenance costs and potential safety hazards.

1.2 Research Objectives and Scope

The objective of this paper is to conduct a comprehensive analysis of existing rust detection technologies for tower steel structures. It aims to systematically review the principles, advantages, and limitations of common detection methods, explore the application of new technologies in this field, and predict the future development trends of rust detection technology.

The research scope includes but is not limited to the following aspects. First, traditional non – destructive testing methods for rust detection, such as visual inspection, magnetic flux leakage detection, and ultrasonic testing, will be analyzed in detail. Second, emerging technologies like electrochemical impedance spectroscopy, infrared thermography, and intelligent sensor – based detection methods will be explored. Finally, the future development trends of rust detection technology, including the integration of multiple technologies, the application of artificial intelligence and big data in detection, will also be covered.

1.3 Structure of the Thesis

This thesis is organized as follows. Chapter 2 will introduce the basic knowledge of tower steel structures, including their structural forms, materials, and the mechanism of rust formation. This part will lay a theoretical foundation for the subsequent study of rust detection technology.

Chapter 3 will focus on common rust detection methods for tower steel structures. It will explain the working principles, operation processes, and application scenarios of each method, and compare their advantages and disadvantages through practical cases.

Chapter 4 will explore new technologies applied in rust detection. It will introduce the principles and characteristics of emerging technologies, and discuss their potential application prospects and challenges in the field of tower steel structure rust detection.

Chapter 5 will analyze the future development trends of rust detection technology, considering factors such as technological innovation, the development of materials science, and the requirements of the industry.

Finally, Chapter 6 will summarize the research content of the entire thesis, draw conclusions, and put forward some suggestions for future research and practical applications. Through this logical structure, readers can have a clear understanding of the development process and future direction of tower steel structure rust detection technology.

2. Theoretical Foundation of Tower Steel Structure Rust

2.1 Mechanism of Steel Structure Rusting

2.1.1 Chemical Reactions in Rust Formation

Steel is primarily composed of iron (Fe), and when tower steel structures are exposed to the atmosphere, a series of complex electrochemical reactions occur. The rusting process of iron is mainly an electrochemical corrosion reaction. In the presence of water and oxygen, iron acts as an anode and undergoes oxidation. The chemical equation for the oxidation of iron at the anode is:

$$Fe \rightarrow Fe^{2+} + 2e^{-}$$

. Here, iron atoms lose electrons and are oxidized to ferrous ions ($$Fe^{2+}$$

).At the cathode, oxygen and water gain electrons. The reaction equation is:

$$O_{2}+2H_{2}O + 4e^{-}\rightarrow4OH^{-}$$

. The ferrous ions ($$Fe^{2+}$$

) produced at the anode react with the hydroxide ions ($$OH^{-}$$

) generated at the cathode. The resulting product is ferrous hydroxide ($$Fe(OH)_{2}$$

), which is further oxidized by oxygen in the air to form ferric hydroxide ($$Fe(OH)_{3}$$

). The chemical equation for this oxidation process is: $$4Fe(OH)_{2}+O_{2}+2H_{2}O\rightarrow4Fe(OH)_{3}$$

. Ferric hydroxide is unstable and will decompose to form rust, which is mainly composed of iron(III) oxide ($$Fe_{2}O_{3}$$

) and its hydrated forms such as $$Fe_{2}O_{3}·nH_{2}O$$

. This series of chemical reactions gradually leads to the formation of the reddish – brown rust layer that is commonly observed on the surface of steel structures.2.1.2 Influence of Environmental Factors

Humidity: Humidity plays a crucial role in the rusting process. Water is an essential medium for the electrochemical reactions of rust formation. When the relative humidity in the environment is high, a thin water film is easily formed on the surface of the steel structure. This water film provides an electrolyte environment for the transfer of ions, accelerating the electrochemical corrosion reaction. For example, in coastal areas where the air humidity is often above 80%, tower steel structures are more likely to rust compared to arid inland areas. Research has shown that when the relative humidity exceeds 60%, the rusting rate of steel begins to increase significantly.

pH Value: The acidity or alkalinity of the environment also affects the rusting rate. In an acidic environment, hydrogen ions (

$$H^{+}$$

) can participate in the electrochemical reaction. The reaction equation is $$Fe + 2H^{+} \rightarrow Fe^{2+} + H_{2}\uparrow$$

. Acidic substances such as sulfur dioxide ($$SO_{2}$$

) and nitrogen oxides ($$NO_{x}$$

) in the atmosphere can dissolve in water to form acidic solutions, which accelerate the corrosion of steel. In contrast, in a highly alkaline environment, although the corrosion rate of steel is relatively slow under normal circumstances, if there are certain aggressive anions present, it can also cause corrosion. For instance, in industrial areas with high levels of acidic pollutants, the corrosion of tower steel structures is much more severe.Temperature: Temperature affects the rate of chemical reactions. Generally, within a certain temperature range, an increase in temperature can accelerate the rusting process. Higher temperatures increase the kinetic energy of molecules and ions, promoting the diffusion of reactants and products in the electrochemical reaction system. However, when the temperature is too high, it may also cause the evaporation of the water film on the steel surface, which inhibits the rusting reaction to some extent. For example, in tropical regions with high temperatures and high humidity, the rusting rate of tower steel structures is much faster than in temperate regions.

2.2 Hazards of Rust on Tower Steel Structure

2.2.1 Reduction of Structural Strength

From a mechanical point of view, rust is a porous and brittle substance. When rust forms on the surface of a steel structure, it occupies space and gradually reduces the cross – sectional area of the steel member. According to the formula for axial force bearing capacity

$$N = fA$$

(where $$N$$

is the bearing capacity, $$f$$

is the allowable stress of the material, and $$A$$

is the cross – sectional area), as the cross – sectional area $$A$$

decreases due to rust, the bearing capacity of the steel member will also decrease.Moreover, the presence of rust can cause stress concentration at the interface between the rust layer and the steel matrix. Stress concentration can lead to the initiation and propagation of cracks in the steel. Once cracks appear and expand, they will further reduce the strength and ductility of the steel, seriously threatening the structural integrity of the tower steel structure. For example, in a power transmission tower, if the main supporting members are corroded and their cross – sectional areas are reduced by 10%, the bearing capacity of the entire tower may be reduced by more than 20%, which greatly increases the risk of structural failure.

2.2.2 Impact on Service Life

The corrosion of tower steel structures accelerates the aging process of the structure. A case in point is a communication tower built in an industrial area in the 1990s. Due to the high – pollution environment in the area, the tower steel structure suffered severe corrosion. In just over a decade, the corrosion degree of the tower was much higher than that of similar towers in less – polluted areas. The originally designed service life of the tower was 25 years, but due to severe rusting, it had to be replaced after only 15 years of use.

Rust not only damages the material properties of the steel but also weakens the connection between components. Loose connections can lead to increased structural vibrations under external loads such as wind and earthquake, further accelerating the degradation of the structure. As a result, the normal service life of the tower steel structure is shortened, and more frequent maintenance and replacement are required, increasing maintenance costs and reducing the overall economic benefits of the project.

3. Common Rust Detection Methods for Tower Steel Structure

3.1 Visual Inspection Method

3.1.1 Inspection Process and Features

The visual inspection method is the most basic and straightforward approach for detecting rust on tower steel structures. During the inspection process, inspectors directly observe the surface of the steel structure with the naked eye or with the aid of some simple tools such as magnifying glasses. They look for signs of rust, such as the presence of reddish – brown rust spots, changes in the surface color of the steel from its original metallic luster to a duller appearance, and the formation of rust layers of varying thicknesses. In some cases, they may also use scrapers to gently remove the outer layer of rust to better assess the degree of corrosion underneath.

This method has several distinct features. Firstly, it is extremely simple and does not require any complex or expensive equipment. Inspectors can quickly identify obvious rust problems on the surface of the steel structure. Secondly, it provides immediate results. As long as the inspection is carried out, the presence and approximate location of surface rust can be determined on – the – spot. However, it also has significant drawbacks. It is highly subjective, as different inspectors may have different judgments about the degree of rust. Moreover, it can only detect surface – level rust and is unable to provide information about the internal corrosion situation of the steel structure, which may lead to underestimation of the actual corrosion damage.

3.1.2 Application Scenarios and Limitations

Visual inspection is most suitable for preliminary inspections of tower steel structures. For example, during routine maintenance checks of communication towers, workers can first use visual inspection to quickly scan the entire structure to identify any obvious rust areas. It is also effective when the surface rust is very obvious, such as in the case of severely corroded steel structures in coastal areas with high humidity and salt – laden air, where the rust can be easily spotted.

However, its limitations are also evident. Since it can only detect surface rust, for steel structures with internal corrosion that is not yet visible on the surface, this method is ineffective. In addition, for tower steel structures with complex geometries or those that are difficult to access, visual inspection may not be comprehensive enough. For instance, in some high – voltage transmission towers with narrow spaces between components or in hard – to – reach areas, it is challenging to conduct a thorough visual inspection, and hidden rust problems may be overlooked.

3.2 Electrochemical Detection Method

3.2.1 Basic Principles (such as Linear Polarization Resistance Method)

The linear polarization resistance method is a common electrochemical detection principle for rust detection in tower steel structures. In an electrochemical system, when a small polarization potential is applied to the steel structure (the working electrode) in an electrolyte environment (such as the thin water film on the surface of the steel structure containing dissolved oxygen and other substances), a corresponding polarization current will flow. According to Faraday’s law and the principles of electrochemical kinetics, there is a relationship between the corrosion rate (

$$v$$

) of the steel and the polarization resistance ($$R_{p}$$

). The corrosion rate can be expressed as $$v = \frac{B}{R_{p}}$$

, where $$B$$

is a constant related to the electrochemical reaction mechanism of the steel in the specific environment. By measuring the polarization resistance $$R_{p}$$

, the corrosion rate of the steel can be calculated, and thus the degree of rusting can be determined. When the steel structure is in a more severely corroded state, the corrosion rate is higher, and the polarization resistance is lower.3.2.2 Instrumentation and Operation Steps

Commonly used electrochemical detection instruments include corrosion potential meters. The operation steps are as follows: First, prepare the working electrode, reference electrode, and counter – electrode. The working electrode is usually the steel structure itself or a small piece of the same – type steel attached to the structure. The reference electrode provides a stable potential reference, and the counter – electrode is used to complete the electrochemical circuit. Then, connect these electrodes to the corrosion potential meter. Next, place the electrodes in the appropriate electrolyte environment on the surface of the steel structure. After that, start the instrument to apply a small polarization potential and measure the resulting polarization current. Finally, according to the measured data, calculate the polarization resistance and then determine the corrosion rate and the degree of rusting through relevant formulas.

During the operation, several precautions need to be taken. The electrodes must be properly installed to ensure good electrical contact with the steel structure and the electrolyte. The selection of the reference electrode should be appropriate for the specific environment of the steel structure. Also, the measurement should be carried out in a relatively stable environment to avoid interference from external factors such as sudden changes in temperature and humidity.

3.2.3 Advantages and Disadvantages

One of the significant advantages of the electrochemical detection method is its fast detection speed. Once the instrument is set up and the measurement is started, the results can be obtained relatively quickly, which is very suitable for on – site inspections where time is limited. It also has high sensitivity and can detect even slight corrosion changes in the steel structure. However, this method is highly susceptible to environmental interference. For example, changes in the composition of the electrolyte (such as the concentration of dissolved oxygen and the presence of other impurities in the water film on the steel surface), temperature fluctuations, and the presence of electromagnetic fields can all affect the accuracy of the measurement results. In addition, the electrochemical detection method requires a certain level of professional knowledge and skills for operation and data analysis, which may limit its widespread application among non – professional personnel.

3.3 Nondestructive Testing Methods

3.3.1 Ultrasonic Testing

The principle of ultrasonic testing for rust detection in tower steel structures is based on the behavior of ultrasonic waves when they encounter different media. When ultrasonic waves are transmitted into the steel structure, they travel at a certain speed. If there is a rust layer or corrosion – related defects inside the steel structure, the ultrasonic waves will experience reflection and refraction at the interface between the sound – conducting steel matrix and the non – sound – conducting rust layer. The reflected ultrasonic waves can be received by the transducer. By analyzing the time delay, amplitude, and phase of the received ultrasonic signals, information about the location, size, and shape of the rust – related defects can be obtained. For example, a large rust – filled cavity inside the steel structure will cause a strong reflection of ultrasonic waves, resulting in a high – amplitude echo signal received by the transducer.

3.3.2 Magnetic Flux Leakage Testing

Steel has a certain magnetic permeability. In magnetic flux leakage testing, a magnetic field is applied to the tower steel structure. When the steel structure is in a normal state, the magnetic lines of force are evenly distributed within the steel. However, when there is rust or corrosion in the steel structure, the magnetic permeability of the rust – affected area changes. Rust has a much lower magnetic permeability compared to the steel matrix. As a result, the magnetic lines of force will leak out from the rust – affected area, forming a magnetic flux leakage field. Special magnetic sensors can be used to detect this magnetic flux leakage field. The strength and distribution of the detected magnetic flux leakage signal are related to the size and location of the rust defect. For instance, a larger rust area will produce a stronger magnetic flux leakage signal, allowing inspectors to determine the severity of the rust problem.

3.3.3 Comparison of Nondestructive Testing Methods

In terms of detection depth, ultrasonic testing can penetrate relatively deep into the steel structure, usually able to detect internal rust defects at a certain depth, depending on the frequency of the ultrasonic waves used and the type of steel. Magnetic flux leakage testing is more suitable for detecting surface – near and shallow – depth rust defects. For detection accuracy, ultrasonic testing can provide relatively accurate information about the location and size of internal rust defects with the help of advanced signal – processing techniques. Magnetic flux leakage testing can also accurately locate surface – near rust areas but may have some limitations in precisely measuring the size of deep – seated defects.

Regarding the applicable range, ultrasonic testing is suitable for a wide variety of steel structures, regardless of their magnetic properties. Magnetic flux leakage testing is mainly applicable to ferromagnetic steel structures, as non – ferromagnetic materials do not respond well to the magnetic field in this testing method. In summary, each nondestructive testing method has its own characteristics, and in practical applications, a combination of multiple methods may be used to achieve more comprehensive and accurate rust detection results for tower steel structures.

4. Case Studies of Rust Detection in Tower Steel Structure

4.1 Case One: Application of Visual Inspection in a Transmission Tower

4.1.1 Project Background

The transmission tower in question was constructed in 1995 and is located in a suburban area near an industrial park in the southern part of a certain city. The area experiences high humidity throughout the year, with an average relative humidity of around 70%, and is also affected by industrial pollutants such as sulfur dioxide emitted from nearby factories. The tower is a key component of the local power grid, responsible for transmitting high – voltage electricity from a power plant to the urban area, with a height of 80 meters and a lattice – type structure made of Q345 steel.

4.1.2 Visual Inspection Results and Analysis

During a routine visual inspection carried out by the power grid maintenance team in 2020, several areas of concern were identified. Firstly, at the lower part of the tower, close to the ground, obvious reddish – brown rust spots were observed on many of the main support members. The rust layer was relatively thick in some areas, with a thickness estimated to be about 2 – 3 mm by scraping with a simple tool. In addition, the connecting parts between the main members and the cross – braces also showed signs of rust, and some of the bolts appeared to be corroded, with their surfaces losing their original luster.

The possible reasons for the rusting are as follows. The high humidity in the area provides a favorable environment for the electrochemical corrosion reactions of rust formation. The water film on the surface of the steel structure serves as an electrolyte, facilitating the transfer of ions during the corrosion process. The industrial pollutants, especially sulfur dioxide, dissolve in the water film to form acidic substances. These acidic substances react with the steel, accelerating the corrosion rate. For example, sulfur dioxide can react with water to form sulfurous acid (

$$H_{2}SO_{3}$$

), which further oxidizes to sulfuric acid ($$H_{2}SO_{4}$$

) in the presence of oxygen. The sulfuric acid then reacts with iron in the steel, leading to the formation of iron sulfate and hydrogen gas, thereby promoting the rusting process.4.2 Case Two: Electrochemical Detection in a Communication Tower

4.2.1 Tower Information and Detection Requirements

The communication tower is located in a coastal city and was built in 2008. It is a 50 – meter – high self – standing three – tube tower made of stainless – steel alloy, mainly used to support communication antennas for mobile network operators. Due to its proximity to the sea, the tower is constantly exposed to a high – salt and high – humidity environment. The operators require regular and accurate detection of the tower’s corrosion status to ensure the stable operation of the communication network. They are particularly concerned about the initial stages of corrosion, as even slight corrosion in key components could potentially affect the structural stability of the tower and the quality of communication signals.

4.2.2 Electrochemical Detection Process and Data Analysis

The electrochemical detection was carried out using a professional corrosion monitoring system based on the linear polarization resistance method. Before the test, the working electrode was carefully attached to the surface of the tower’s main tube, the reference electrode was placed in a stable position close to the working electrode, and the counter – electrode was set up to complete the electrochemical circuit. The instrument was calibrated to ensure accurate measurement.

During the detection process, a small polarization potential was applied, and the resulting polarization current was measured at regular intervals. The data collected over a period of one hour showed that the polarization resistance values in some areas of the tower were relatively low. For example, at a position about 10 meters above the ground on one of the main tubes, the polarization resistance was measured to be 1000 ohm·cm², which indicated a relatively high corrosion rate in this area. According to the formula

$$v = \frac{B}{R_{p}}$$

(where $$B$$

was determined to be 26 mV based on the characteristics of the stainless – steel alloy and the local environment), the corrosion rate in this area was calculated to be 0.026 mm/year.By analyzing the data from different positions of the tower, it was found that the areas closer to the ground and those facing the sea had lower polarization resistance values, indicating more severe corrosion. This was consistent with the fact that these areas were more exposed to the high – salt and high – humidity sea – breeze environment. In addition, by comparing the data collected over several consecutive detection periods, it was observed that the corrosion rate in some areas was gradually increasing, suggesting a potential risk of accelerated corrosion if no preventive measures were taken.

4.3 Case Three: Comprehensive Application of Nondestructive Testing in a Large – Scale Tower

4.3.1 Tower Structure and Complexity

The large – scale tower is a 200 – meter – high lattice – type tower located in a mountainous area and was constructed in 2010. It is used for both power transmission and communication purposes, with a complex structure that includes multiple levels of platforms, numerous cross – braces, and different – sized steel members. The tower is made of high – strength steel, but its complex geometry and the harsh mountain environment, which includes strong winds, temperature variations, and occasional acidic rain due to air pollutants carried by the wind from nearby industrial areas, pose great challenges to the rust detection work. The presence of various components and the difficulty of accessing some parts of the tower make it difficult to obtain a comprehensive understanding of its rust situation through a single detection method.

4.3.2 Selection and Application of Nondestructive Testing Methods

To address the challenges, a combination of ultrasonic testing and magnetic flux leakage testing was selected. Ultrasonic testing was chosen because it can effectively detect internal rust defects in the thick – walled steel members of the tower, regardless of their magnetic properties. Magnetic flux leakage testing was added to specifically target surface – near and shallow – depth rust defects in the ferromagnetic steel components, which are more likely to be affected by environmental factors.

During the ultrasonic testing, ultrasonic transducers with different frequencies were used to ensure the detection of rust defects at different depths. High – frequency transducers were used for detecting shallow – depth defects, while low – frequency transducers were applied for deeper – seated defects. The transducers were carefully moved along the surface of the steel members, and the received ultrasonic signals were continuously monitored and recorded.

For magnetic flux leakage testing, a portable magnetic flux leakage detector was used. The detector was moved slowly over the surface of the ferromagnetic steel components, and the magnetic flux leakage signals were detected and analyzed in real – time. Special attention was paid to the areas where stress concentration was likely to occur, such as the connection points of the members.

4.3.3 Integrated Analysis of Detection Results

After the completion of both ultrasonic testing and magnetic flux leakage testing, the data from the two methods were comprehensively analyzed. The ultrasonic testing results showed that there were several internal rust – filled cavities in some of the main support members at a depth of 5 – 10 mm from the surface. The sizes of these cavities ranged from 10 – 30 mm in diameter. The magnetic flux leakage testing results indicated that there were numerous surface – near rust defects, especially in the areas around the connection points of the members. These surface – near rust defects were mainly in the form of small pits and grooves, with a maximum depth of about 2 mm.

By integrating the two sets of data, it was possible to obtain a more complete picture of the tower’s rust situation. The internal rust defects detected by ultrasonic testing, although not visible from the surface, posed a significant threat to the structural strength of the main members. The surface – near rust defects detected by magnetic flux leakage testing, if left untreated, could potentially develop into more serious internal corrosion over time. Based on this comprehensive assessment, a detailed maintenance plan was formulated, which included targeted anti – corrosion treatment for both the internal and surface – near rust areas to ensure the long – term safety and stability of the large – scale tower.

5. New Developments and Trends in Tower Steel Structure Rust Detection Technology

5.1 Introduction of New Detection Technologies

5.1.1 Fiber – Optic Sensor Technology

Fiber – optic sensor technology has emerged as a promising approach for detecting rust in tower steel structures. The basic principle of fiber – optic sensors lies in their ability to utilize the changes in optical signals to detect physical parameters related to the steel structure. In the context of rust detection, fiber – optic sensors are often used to monitor the strain and corrosion – induced changes in the steel.

Most fiber – optic sensors operate based on the principle of light propagation in optical fibers. When a fiber – optic sensor is attached to a tower steel structure, any deformation or strain in the steel due to rust – induced degradation will cause changes in the physical properties of the optical fiber. For example, the corrosion of the steel can lead to local stress concentrations, which in turn cause the optical fiber to experience micro – bends or changes in its refractive index. These changes affect the transmission of light within the fiber, such as the intensity, phase, or wavelength of the light signal. By precisely measuring these changes in the light signal, the strain and corrosion state of the steel structure can be inferred.

One of the significant advantages of fiber – optic sensor technology is its high sensitivity. It can detect very small changes in strain and corrosion, which may be undetectable by traditional methods. For instance, fiber – optic sensors can detect strain changes in the order of micro – strains, enabling early detection of the initial stages of rust – induced damage in tower steel structures. Moreover, fiber – optic sensors are immune to electromagnetic interference, which is particularly beneficial in environments where tower steel structures are often exposed to strong electromagnetic fields, such as near power transmission lines. This immunity ensures the reliability and accuracy of the detection results. Additionally, fiber – optic sensors can be easily integrated into the structure during the construction phase, providing long – term, real – time monitoring capabilities. They can be distributed along the length of the steel members, allowing for comprehensive monitoring of the entire structure.

5.1.2 Infrared Thermography Technology

Infrared thermography technology is another innovative approach for rust detection in tower steel structures. This technology is based on the principle that when a steel structure is in a normal state, its surface temperature distribution is relatively uniform under the same environmental conditions. However, when rust occurs, the thermal properties of the steel surface change. Rust is a poor thermal conductor compared to the steel matrix. As a result, when an external heat source (such as sunlight or an artificial heating source) acts on the steel structure, the heat dissipation rate in the rust – affected areas is different from that in the normal areas.

In an infrared thermography system, an infrared camera is used to capture the infrared radiation emitted by the surface of the tower steel structure. The infrared radiation is directly related to the surface temperature of the object. The camera converts the infrared radiation into an electrical signal, which is then processed and displayed as a thermal image. In this thermal image, areas with different temperatures are represented by different colors or grayscale values. For a tower steel structure with rust, the rust – affected areas will appear as regions with abnormal temperature distributions in the thermal image. For example, if a part of the steel structure is corroded, the rust layer on its surface will cause the area to heat up more slowly or cool down more quickly than the surrounding normal areas when exposed to the same heat source. This temperature difference is clearly visible in the infrared thermal image, allowing inspectors to accurately identify the location and extent of the rust.

Infrared thermography technology offers several advantages. It is a non – contact detection method, which means that it can be used to inspect tower steel structures in hard – to – reach or dangerous areas without the need for direct physical contact. This is especially useful for tall towers or structures in difficult – to – access terrains. Additionally, it can quickly scan a large area of the steel structure, providing a comprehensive overview of the surface condition in a short time. However, it also has some limitations. The accuracy of infrared thermography is affected by factors such as the surface emissivity of the steel, environmental temperature, and the presence of other heat – generating sources in the vicinity. Therefore, proper calibration and environmental control are necessary to obtain reliable detection results.

5.2 Integration of Multiple Detection Technologies

5.2.1 Complementary Advantages of Technology Integration

The integration of multiple detection technologies has become an important trend in tower steel structure rust detection. Each detection technology has its own unique advantages and limitations. By combining different technologies, it is possible to compensate for the deficiencies of individual methods and achieve more accurate and reliable detection results.

For example, visual inspection can easily identify obvious surface rust, but it is limited to surface – level observations and cannot detect internal corrosion. Electrochemical detection methods are highly sensitive to the early stages of corrosion but are easily affected by environmental factors. Nondestructive testing methods like ultrasonic testing can detect internal defects but may have limitations in accurately identifying the nature of the defects in some cases. When these technologies are integrated, visual inspection can be used as a preliminary screening method to quickly locate areas of potential concern on the surface of the tower steel structure. Electrochemical detection can then be applied in these identified areas to precisely measure the corrosion rate and the degree of rusting. Ultrasonic testing can be used to further investigate the internal condition of the steel structure in areas where internal corrosion is suspected, providing detailed information about the location and size of internal rust – related defects.

The integration of fiber – optic sensor technology and infrared thermography technology also has complementary advantages. Fiber – optic sensors can provide real – time, continuous monitoring of the strain and corrosion – induced changes in the steel structure at specific points or along a certain length. Infrared thermography, on the other hand, can provide a large – scale, non – contact view of the surface temperature distribution of the entire structure, which helps in identifying areas with abnormal heat dissipation patterns that may be related to rust. By combining these two technologies, a more comprehensive understanding of the rust situation in the tower steel structure can be obtained, both in terms of the internal structural changes and the surface – level manifestations.

5.2.2 Examples of Integrated Detection Systems

In recent years, several integrated detection systems have been developed and applied in practical engineering. One such example is a system that combines ultrasonic testing, magnetic flux leakage testing, and electrochemical detection for the inspection of large – scale power transmission tower steel structures.

The system is composed of multiple subsystems. The ultrasonic testing subsystem consists of high – precision ultrasonic transducers, signal amplifiers, and data acquisition units. The magnetic flux leakage testing subsystem includes powerful magnetic field generators, sensitive magnetic sensors, and data processing modules. The electrochemical detection subsystem is equipped with corrosion potential meters, electrodes, and electrochemical analysis software.

During the operation of this integrated detection system, first, the magnetic flux leakage testing is carried out to quickly scan the surface – near areas of the steel structure for any signs of rust – induced magnetic anomalies. The detected magnetic flux leakage signals are immediately analyzed to identify potential rust – affected areas. Then, in these identified areas, electrochemical detection is performed to measure the corrosion rate and the degree of rusting more accurately. Finally, ultrasonic testing is applied to further investigate the internal condition of the steel structure in the areas where internal corrosion is suspected based on the previous two tests. The data from all three subsystems are integrated and analyzed using a central data processing unit. This unit uses advanced algorithms to cross – reference the data from different subsystems, eliminating false positives and providing a more accurate assessment of the rust situation.

In a practical application in a large – scale power grid, this integrated detection system was used to inspect a group of aging power transmission towers. The results showed that it could detect a wider range of rust – related problems compared to using a single detection method. It was able to accurately identify not only surface – near rust defects but also internal corrosion cavities that were previously undetected by traditional methods. As a result, maintenance personnel were able to develop more targeted and effective maintenance plans, significantly improving the safety and reliability of the power transmission towers.

5.3 Application of Intelligent Algorithms in Rust Detection

5.3.1 Principle of Machine Learning Algorithm in Data Analysis

Machine learning algorithms, especially neural networks, have found increasing applications in the analysis of rust detection data for tower steel structures. Neural networks are composed of multiple layers of interconnected nodes (neurons). In the context of rust detection, a neural network is first trained using a large amount of labeled data. This labeled data includes information about the characteristics of the tower steel structure (such as its material properties, geometric dimensions), the environmental conditions (humidity, temperature, pH value), and the corresponding rust detection results obtained from various detection methods (visual inspection data, electrochemical detection data, ultrasonic testing data, etc.).

During the training process, the neural network adjusts the weights of the connections between neurons to minimize the difference between the predicted results and the actual labeled data. For example, in a feed – forward neural network used for rust detection, the input layer receives the various data features related to the steel structure and the detection results. These data are then processed through hidden layers, where complex non – linear transformations are applied to extract meaningful patterns. Finally, the output layer provides the predicted rust status of the steel structure, such as the degree of rusting, the location of rust defects, and the probability of future corrosion.

Deep learning neural networks, which have multiple hidden layers, can automatically learn hierarchical features from the raw data. For instance, in analyzing ultrasonic testing signals for rust detection, a deep – learning neural network can learn to distinguish between normal ultrasonic signals and signals corresponding to different types and degrees of rust – related defects. It can also take into account the complex relationships between different factors, such as how the environmental humidity and temperature interact with the corrosion process and how these factors affect the detection signals.

5.3.2 Advantages of Intelligent Detection

The application of intelligent algorithms in rust detection offers several significant advantages. Firstly, it enables automatic identification and assessment of the rust situation in tower steel structures. Instead of relying on manual interpretation of detection data, which is time – consuming and prone to human error, intelligent algorithms can quickly and accurately analyze large volumes of data. For example, in a large – scale tower inspection project where thousands of data points are collected from multiple detection methods, an intelligent algorithm can process all the data in a short time and provide a comprehensive assessment of the rust status of the entire tower.

Secondly, intelligent detection can improve the accuracy of rust detection. By learning from a large amount of historical data and the complex relationships between different factors, machine – learning algorithms can make more accurate predictions about the rust situation. They can identify subtle patterns in the data that may be overlooked by human inspectors, leading to more precise determination of the location, extent, and severity of rust.

Moreover, intelligent algorithms can adapt to different tower steel structures and environmental conditions. They can continuously update their models based on new data, making them suitable for a wide range of applications. For example, if a new type of tower steel structure is introduced or the environmental conditions in a certain area change significantly, the intelligent algorithm can be retrained using the new data to ensure its effectiveness in rust detection. Overall, the application of intelligent algorithms in rust detection represents a major step forward in improving the efficiency and accuracy of tower steel structure maintenance and management.

6. Conclusion and Outlook

6.1 Summary of Research Findings

Throughout this research, a comprehensive exploration of rust detection technologies for tower steel structures has been conducted. Traditional detection methods, such as visual inspection, are simple and intuitive, enabling quick identification of surface – level rust. However, they are highly subjective and limited to surface observations, failing to detect internal corrosion. Electrochemical detection methods, like the linear polarization resistance method, offer high sensitivity and rapid results, but their accuracy is easily compromised by environmental factors. Nondestructive testing methods, including ultrasonic testing and magnetic flux leakage testing, can detect internal and surface – near rust defects respectively, with ultrasonic testing suitable for deep – seated defect detection in various steel structures and magnetic flux leakage testing mainly applicable to ferromagnetic steel structures.

New detection technologies, such as fiber – optic sensor technology, provide high – sensitivity, real – time monitoring with immunity to electromagnetic interference. Infrared thermography technology, on the other hand, allows for non – contact, large – area scanning to identify rust – related abnormal temperature distributions, although it is affected by surface emissivity and environmental factors.

The integration of multiple detection technologies has proven to be highly beneficial. By combining different methods, the complementary advantages can be utilized to overcome the limitations of individual techniques. For example, visual inspection for surface screening, electrochemical detection for precise corrosion rate measurement, and ultrasonic testing for internal defect investigation can provide a more comprehensive and accurate assessment of the rust situation.

6.2 Challenges and Opportunities in Future Research

Despite the progress in rust detection technologies, several challenges remain. In terms of accuracy, current methods still struggle to precisely measure the degree of corrosion in complex steel structures, especially when dealing with multiple types of corrosion co – existing or in hard – to – access areas. The adaptability to complex environments is another significant challenge. Tower steel structures are often located in diverse environments, such as high – altitude, high – humidity, or chemically – polluted areas. Existing detection technologies may not function optimally in these conditions. For instance, electrochemical detection methods are severely affected by changes in the electrolyte composition in polluted environments, and infrared thermography can be distorted by extreme temperature variations.

However, emerging technologies also bring numerous opportunities. The development of nanotechnology may lead to the creation of more sensitive sensors with enhanced performance. For example, nanosensors could potentially detect trace amounts of corrosion – related substances in the environment around the tower steel structure, enabling even earlier detection of rust. The continuous advancement of artificial intelligence and machine learning algorithms provides the opportunity to develop more intelligent and self – adapting detection systems. These algorithms can analyze large volumes of data from multiple sensors and environmental parameters, improving the accuracy and reliability of rust detection.

6.3 Prospects for the Development of Tower Steel Structure Rust Detection Technology

Looking ahead, the rust detection technology for tower steel structures is expected to develop towards greater intelligence. Intelligent detection systems will be able to automatically analyze and diagnose the rust situation, providing real – time alerts and maintenance recommendations. For example, a fully – integrated intelligent system could continuously monitor the tower’s condition using a combination of sensors and machine – learning algorithms, and when it detects abnormal corrosion trends, it can immediately notify maintenance personnel and suggest appropriate preventive measures.

Multifunctionalization is another important development direction. Future detection technologies will not only be able to detect rust but also assess other factors related to the structural integrity of the tower, such as fatigue damage, stress concentration, and material degradation. This comprehensive assessment will help in making more informed decisions regarding the maintenance and renovation of tower steel structures. Additionally, with the increasing demand for sustainable development, environmentally friendly detection technologies will also be a focus of future research. These technologies will minimize the impact on the environment during the detection process while ensuring high – quality detection results, contributing to the long – term safety and stability of tower steel structures in an environmentally responsible manner.

References

[1] Zhang, G., Zhang, G., Liu, X., & Zhang, Z. (2010). Detection of steel corrosion. Sichuan Building Materials, 36(5), 56-57. [2] Tan, J., Long, Z., Chen, J., Huang, L., & Lin, C. (2014). Analysis on corrosion of transmission tower and related factors in Guangdong coastal area. Journal of Guangdong University of Technology, 31(11), 116-119. [3] Chen, Y., Yao, N., Xu, L., Kong, X., & Wang, B. (2015). Discussion on rusting grade classification of transmission line steel tower. North China Electric Power, (4), 30-34. [4] Bellis, D., & Deacon, J. (2005). Corrosion control of steel structures. Beijing: Chemical Industry Press. [5] Chen, Y., Tian, L., Wu, Y., Song, T., Yan, X., & Yang, S. (2006). Phosphating solution formula for pre – treatment of rusted transmission towers before painting. Corrosion & Protection, 27(6), 294-296. [6] Guo, J., Lu, L., Song, Z., & Zhang, J. (2007). Full chemical anti – corrosion treatment of high – voltage transmission line towers. North China Electric Power, (A01), 153-156. [7] Li, W., Zuo, Y., Xiong, J., & Cao, J. (2008). EIS characteristics of the failure process of composite coating systems under different surface treatment conditions. Journal of Chemical Industry and Engineering (China), 59(2), 420-425. [8] Zhang, Z., Xiong, J., Cao, J., & Zuo, Y. (2008). EIS study on the failure behavior of organic coatings under different surface treatment grades. New Technology & New Process, (10), 90-93. [9] Xu, Y., Yan, C., Gao, Y., Zhang, S., & Cao, C. (2003). Influence of surface state and treatment on the corrosion of A3 steel and the failure of coatings under the coatings. Corrosion Science and Protection Technology, 15(4), 208-211.