Seismic-Resistant Communication Towers – design and maintenance

November 20, 2025

Overhead Transmission Line Towers Technical Analysis

November 29, 2025communications tower – Quality Control and Non-Destructive Testing (NDT)

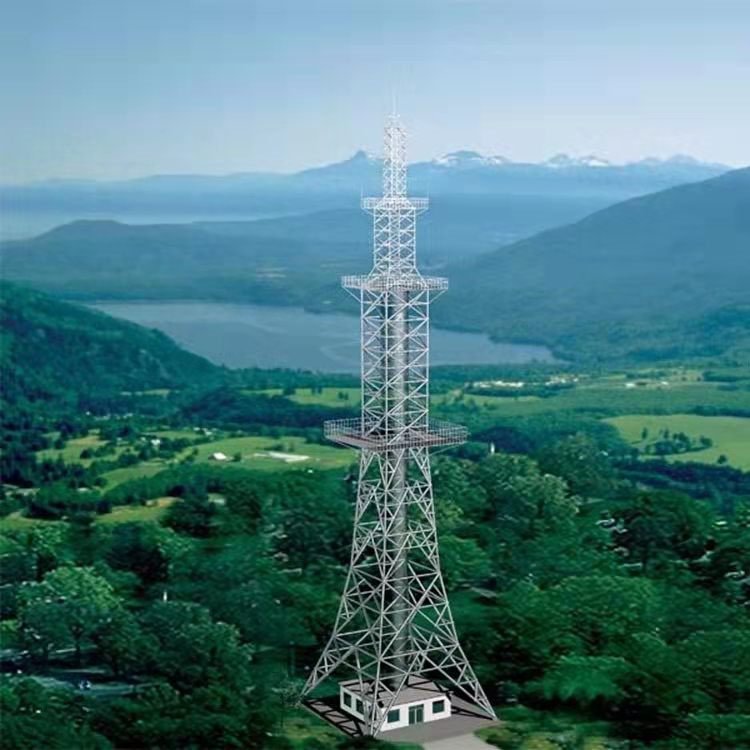

The integrity and longevity of a communications tower, the silent, omnipresent giants of the modern digital landscape, are not merely matters of structural engineering aesthetics but are fundamentally tied to the continuity of global commerce, emergency services, and social connection, making the identification and mitigation of common quality issues a critical and ongoing function within the telecommunications infrastructure sector. These towers—ranging from towering lattice structures and slender monopoles to guyed masts—are subjected to a relentless barrage of environmental and operational stressors: cyclic wind loading, temperature extremes, aggressive corrosive agents, fatigue from vibration, and the cumulative impact of construction and subsequent equipment upgrades, all of which conspire to induce a spectrum of quality defects that, if left unaddressed, can escalate from minor blemishes to catastrophic structural failures, leading to massive financial losses and network outages. Therefore, the discipline of Quality Control and Non-Destructive Testing (NDT) in communication tower maintenance is not a routine task but a highly specialized, forensic engineering practice, requiring a deep, interconnected understanding of materials science, structural mechanics, coating chemistry, and the specific failure modes unique to bolted and welded steel assemblies. This comprehensive discussion must flow organically, beginning with a macroscopic view of the most frequent construction and in-service quality deviations, dissecting the underlying root causes—be they fabrication errors, inadequate protective measures, or foundation settlement—and culminating in a detailed exposition of the sophisticated detection and testing methodologies essential for diagnosing these issues, ensuring a continuous, detailed narrative that captures the full depth and complexity of maintaining these vital assets.

🧱 The Genesis of Defects: Quality Issues in Fabrication and Construction

The seeds of future structural failure in a communications tower are often sown during the initial phases of fabrication and field construction, where deviations from stringent engineering drawings and material specifications introduce inherent flaws that compromise the structure’s intended capacity and longevity, necessitating a vigilant Quality Assurance (QA) process that must extend from the steel mill to the final bolt tightening. A primary source of defects originates in the Fabrication Shop, particularly within the critical realm of Welded Connections on pipe legs, gusset plates, and bracing members, where poor quality control can lead to unacceptable metallurgical discontinuities; common welding defects include Lack of Fusion (where the weld metal fails to fuse completely with the base metal), Porosity (small gas pockets trapped within the weld metal), and Weld Undercut (a groove melted into the base metal adjacent to the weld toe), all of which significantly reduce the effective cross-sectional area and act as severe Stress Concentrators, drastically lowering the fatigue life and static strength of the joint, making it a prime candidate for failure under cyclic wind loads, necessitating the widespread use of codes like AWS D1.1 (Structural Welding Code—Steel) for mandatory defect acceptance criteria. Equally critical are Geometric and Dimensional Deviations, where inaccuracies in cutting, punching, or drilling—such as oversized bolt holes, incorrect bolt hole spacing, or non-perpendicular cuts on leg members—compromise the intended fit-up and load transfer during erection; these dimensional errors force undue stress during assembly, often leading to field modifications like flame-cutting or enlarging holes, modifications that typically go undocumented and severely reduce the structural capacity by compromising the material’s metallurgy and geometric precision.

The protective coating, the tower’s first and often only line of defense against the relentless advance of corrosion, is another significant area for quality compromise, particularly with the ubiquitous Hot-Dip Galvanizing (HDG) process; defects such as Insufficient Coating Thickness (leading to premature zinc consumption and rust), Bare Spots (areas of steel exposed due to inadequate cleaning or fluxing), or White Rust (premature oxidation of the zinc layer) directly lead to a rapid reduction in the planned service life of the corrosion protection system, necessitating costly and complex in-service maintenance decades sooner than anticipated, a failure directly attributable to inadequate control over the galvanizing bath chemistry or dipping procedure. Furthermore, during Field Erection, fundamental errors in assembly—such as Missing or Incorrect Hardware (using the wrong bolt grade or omitting washers), Improper Bolt Tensioning (leading to loose connections that vibrate and fret, causing metal loss), or Incorrect Bracing Orientation—can invalidate the entire structural analysis; loose bolts not only compromise joint strength but also allow excessive movement that accelerates metal fatigue and corrosion in the joint area, transforming a high-strength bolted connection into a high-risk structural vulnerability, thereby demonstrating that even minor construction oversight can undermine the entire complex engineering effort, reinforcing the necessity for stringent, continuous quality verification throughout every stage of the tower’s life.

🌊 Environmental and Operational Degradation: The In-Service Failures

Once a communications tower is successfully erected and commissioned, its operational life becomes a relentless battle against a host of environmental and operational stressors that induce a different category of quality problems, often subtle and progressive, but ultimately equally destructive, requiring a specialized maintenance focus to anticipate and mitigate these in-service failures. Corrosion, the most pervasive and insidious enemy of steel structures, manifests in various forms driven by the local environment: Atmospheric Corrosion (uniform rust) is common in industrial and coastal areas where the concentration of chlorides, sulfur dioxide, and moisture accelerates the breakdown of the protective galvanization, leading to the localized loss of steel thickness in critical load-bearing members; more critically, Crevice Corrosion, often hidden beneath connection plates, washer stacks, or poorly sealed joints, can rapidly deplete the protective zinc layer in localized, oxygen-starved pockets, leading to deep pitting and catastrophic steel loss that is visually undetectable until the damage is severe, making it a high-priority target for inspection.

Fatigue and Vibration Damage represent a constant, dynamic threat, particularly in taller structures or those subjected to sustained, high-velocity winds or dynamic loads from microwave dishes; the cyclical nature of wind loading causes microscopic cracks to initiate at points of stress concentration (like weld toes or bolt holes with sharp edges), which then grow slowly over millions of cycles, eventually leading to sudden, brittle fatigue fracture of a critical member, a failure mode that can occur well below the material’s static yield strength, often manifesting first as Fretting Corrosion or Metal Loss around loose bolt holes due to constant rubbing and vibration, highlighting the critical link between operational looseness and material fatigue. Foundation Settlement and Erosion are also chronic in-service issues that directly compromise the tower’s verticality and structural stability; differential settlement of the underlying soil, caused by changing water tables, nearby construction, or poor initial compaction, can induce massive, unintended secondary stresses and eccentric loads in the tower legs, leading to buckling or severe foundation cracking, a structural problem that demands immediate and often expensive geotechnical remediation, demonstrating that the tower’s integrity is intrinsically tied to the stability of the ground upon which it stands. Finally, Accidental Damage and Modification Failures—often resulting from poor practices during equipment upgrades, such as cutting or drilling into galvanized members without proper surface repair, or the addition of unauthorized antennas that overload the tower’s capacity—introduce new stress points and invalidate the original engineering assumptions, transforming the tower into an un-certified structure with unpredictable failure points, thereby completing the spectrum of in-service defects that necessitate a rigorous and continuous inspection and management regime.

🔎 Detection Methodologies: The Forensic Toolkit for Quality Assessment

The effective management of communication tower quality issues requires moving beyond simple visual inspection, which is often insufficient for detecting critical hidden defects like internal weld flaws, sub-surface cracks, or coating under-performance, demanding the deployment of a specialized, multi-faceted Non-Destructive Testing (NDT) and Diagnostic Toolkit that provides quantitative evidence of the structure’s true condition. For the critical task of verifying Weld Integrity—a mandatory check on all primary load-bearing joints, especially in monopoles and welded leg sections—the gold standard techniques are Ultrasonic Testing (UT) and Magnetic Particle Testing (MPT); $\text{UT}$ utilizes high-frequency sound waves transmitted through the steel to detect internal discontinuities like lack of fusion, slag inclusions, or internal cracks by analyzing the reflected sound signals, providing precise depth and size information, making it essential for verifying the quality of butt welds in pipe legs, while $\text{MPT}$ uses magnetic fields and fine iron particles to identify surface and near-surface cracks and flaws in ferromagnetic materials, an indispensable tool for checking fillet welds and the areas around stress concentrators in connection plates.

To assess the tower’s most visible defense, the Corrosion Protection System, specific tools are required: the Dry Film Thickness ($\text{DFT}$) Meter (a magnetic induction or eddy current gauge) is used to accurately measure the thickness of the galvanizing or paint layer, ensuring compliance with the minimum required coating thickness for long-term protection, with these measurements being rigorously logged and compared against initial specifications to track the rate of coating degradation; simultaneously, Holiday Detectors (high-voltage spark testers) are employed on non-conductive paint coatings to locate invisible pinholes or small discontinuities that could allow moisture access to the steel substrate, ensuring the coating provides a continuous, impervious barrier. For the crucial assessment of Bolt Tension and Joint Integrity, specialized tools are essential: Torque Wrenches are used for final tightening and verification during construction and re-tensioning, while more advanced Ultrasonic Bolt Tension Monitors can non-invasively measure the actual tension or clamping force within a pre-tensioned bolt, providing a much more accurate measure of joint integrity than simple torque checks, ensuring the frictional forces required for high-strength joints are correctly established. Finally, to address the in-service failures linked to deformation, precise Surveying Equipment—such as high-accuracy total stations or laser scanning systems—is used to measure the tower’s overall verticality, plumb, and twist, immediately identifying any unacceptable lean or twist that signals foundation settlement or a serious structural imbalance, providing the quantitative data necessary for remediation planning, collectively forming a forensic engineering process that transforms vague observations into quantifiable, actionable quality control evidence.

📉 Quality Management in the Lifecycle: Data Integration and Remediation

Effective quality management in communication tower operations is not just about detection; it is fundamentally about integrating the diagnostic data into a continuous improvement and maintenance cycle, leading to informed remediation decisions and a predictive approach to asset management, shifting the focus from simply reacting to failures to strategically preventing them, a philosophy known as Total Quality Management (TQM) in the asset lifecycle context. The information generated by the NDT and inspection teams—coating thickness readings, weld defect reports, torque values, and verticality surveys—must be meticulously logged into a centralized Asset Management System (AMS), creating a comprehensive digital twin of the tower that allows engineers to track the historical performance of specific components, calculate the degradation rate of the protective coatings, and forecast the remaining service life of the asset, thereby allowing maintenance budgets and activities to be prioritized based on risk and predictive analytics rather than fixed time schedules. When a significant quality issue is identified—such as a critical weld flaw or severe corrosion—the decision to remediate is governed by the immediate impact on the tower’s structural capacity (calculated based on the defect size and location) and the feasibility of repair.

Remediation Strategies are highly specific to the defect type: for localized corrosion, the standard approach involves thorough surface preparation (e.g., abrasive blasting) followed by the application of a Cold Galvanizing Compound or a multi-layer Polymer Coating System to restore the protective barrier; for defects like loose bolts, the process is straightforward Re-tensioning and Hardware Replacement, often upgrading to more vibration-resistant locking nuts or specialized washers to prevent future recurrence; however, for critical weld defects or members with severe material loss, the solution often requires Excavation and Replacement of the Damaged Member or the application of Welded Reinforcement Plates (fish plates), a high-stakes field operation that must be carried out under the strictest welding code compliance, often requiring the temporary offloading of the member’s stress and full post-weld NDT verification to ensure the repair does not introduce new flaws. Crucially, the quality management system must feed defect data back into the Design and Procurement Process (a closed-loop feedback mechanism); for example, if a company repeatedly finds corrosion problems in a specific type of bolted connection, the engineering department might redesign the connection to use self-sealing gaskets or specify a higher corrosion-resistant bolt grade for future towers, thereby implementing a systemic correction that improves the inherent quality and resilience of the entire tower fleet. This holistic integration of forensic detection, data logging, predictive analysis, and continuous feedback elevates the quality control function from simple inspection to a dynamic, strategic tool for ensuring the perpetual safety and reliability of the communications network infrastructure.

📊 Consolidated Technical Reference Tables for Tower Quality and Testing

The following tables summarize the common quality defects, their root causes, and the primary detection methodologies required for effective quality management in communications tower construction and maintenance, emphasizing the need for advanced NDT techniques.

Table 1: Common Quality Defects and Root Causes

| Defect Type | Location/Phase | Description | Primary Structural Impact | Root Cause |

| Inadequate Weld Penetration/Porosity | Fabrication (Welded Joints) | Internal voids or lack of fusion in critical load-bearing welds. | Reduced Effective Cross-Section, Lowers Fatigue Life | Poor Welding Procedure (WPS), Low Heat Input, Contamination. |

| Coating Under-Thickness/Bare Spots | Fabrication (Galvanizing/Painting) | Protective layer fails to meet specified minimum thickness. | Premature Corrosion, Loss of $20+$ year service life. | Incorrect Dipping Time/Chemistry, Insufficient Surface Preparation. |

| Improper Bolt Tension/Looseness | Erection/In-Service | Bolted connections are under-tightened or have vibrated loose. | Fretting Corrosion, Accelerated Fatigue, Structural Instability. | Inadequate Torque Control, Omission of Lock Hardware. |

| Excessive Plumb/Verticality Deviation | Erection/In-Service | Tower leans or twists beyond acceptable tolerance. | Secondary ($\text{P-Delta}$) Stresses, Unacceptable Antenna Misalignment. | Differential Foundation Settlement, Assembly Errors, Foundation Failure. |

| Crevice Corrosion | In-Service (Bolted Joints) | Localized, deep corrosion hidden between plates or washers. | Loss of Steel Thickness in Critical Areas, Hidden Failure Risk. | Oxygen Depletion in Tight Gap, Water Retention, Chloride Concentration. |

| Unapproved Modification | In-Service (Operations) | Unauthorized cutting, drilling, or addition of excessive equipment load. | Invalidates Engineering Certification, Creates New Stress Concentrators. | Lack of Change Management Protocol, Poor Contractor Control. |

Table 2: Non-Destructive Testing (NDT) and Diagnostic Toolkit

| Testing/Method | Physical Parameter Measured | Typical Application/Target | Defect Identified |

| Ultrasonic Testing (UT) | Internal Material Discontinuities (Reflection/Transmission) | Critical Butt Welds in Monopoles and Pipe Legs. | Internal Cracks, Lack of Fusion, Slag Inclusions. |

| Magnetic Particle Testing (MPT) | Surface and Near-Surface Flaws (Magnetic Flux Leakage) | Fillet Welds, Bolt Holes, High-Stress Zones. | Surface Cracks, Grinding Cracks, Fatigue Cracks. |

| Dry Film Thickness (DFT) Meter | Coating Thickness ($\mu\text{m}$) | $100\%$ of Galvanized/Painted Surfaces. | Insufficient Coating Thickness, Premature Corrosion Risk. |

| Ultrasonic Bolt Tension Monitor | Actual Bolt Tension/Clamping Force | Critical High-Strength Bolted Connections (A490/A325). | Incorrect Pre-tensioning, Loose Bolts. |

| High-Accuracy Total Station/Laser Scan | Tower Verticality, Plumb, Twist, Displacement | Overall Tower Structure and Foundation Levelness. | Foundation Settlement, Severe Plumb Deviation, Buckling. |

| Dye Penetrant Inspection (DPI) | Surface-breaking Flaws | Non-Magnetic Materials (e.g., Aluminum Platforms), Suspect Weld Areas. | Surface Cracks, Porosity (Open to Surface). |

Table 3: Remediation and Quality Management Strategy

| Strategy | Action/Procedure | Goal | Quality Management Link |

| Preventive Action | Re-tensioning of Loose Bolts, Coating Touch-ups. | Prevent minor issues from escalating to structural failure. | Scheduled based on AMS data and inspection reports. |

| Corrective Action | Member Replacement, Structural Weld Repair (with NDT). | Restore lost structural capacity and integrity. | Requires Engineering Review; Full NDT verification post-repair. |

| Life Cycle Data | Centralized Asset Management System ($\text{AMS}$) Logging. | Predictive Maintenance, Budget Prioritization, Failure Root Cause Analysis. | Continuously feeds back defect data to Design/Procurement. |

| Systemic Improvement | Redesigning problematic connections, Specifying better coatings/hardware. | Eliminate recurring defects across the entire asset fleet. | Closed-loop feedback mechanism to the Engineering Department. |

💡 Conclusion: Vigilance as the Ultimate Quality Assurance

The successful management of communication tower quality issues is a commitment to perpetual vigilance, demanding an integrated system that links initial fabrication compliance to the continuous forensic examination of the in-service structure. By embracing advanced NDT methodologies—such as UT for internal weld flaws and high-accuracy surveying for structural plumb—and diligently logging the resulting data into a centralized asset management system, operators can move beyond reactive repair to a strategic, predictive maintenance model. This integrated quality assurance process, which ensures the integrity of the protective coatings, the tightness of every critical bolt, and the metallurgical health of every weld, is the only guarantee that these vital steel sentinels will reliably sustain the communication backbone of the modern world throughout their demanding service life, proving that in critical infrastructure, quality control is synonymous with network reliability.

Would you like me to focus the next discussion on the specific material science aspects of corrosion failure in galvanized steel towers, including the role of zinc electrochemistry and the mechanisms of localized pitting?